Get Nail&Wire Machine Solution

- We offer advanced solutions for wire drawing,nail making ,barbed wire making and chain link fence making. Our automated process allows us to make machine parts with a high degree of precision, ensuring that the end result is uniform and efficient. We also use state-of-the art materials to ensure maximum durability and longevity for each product.

- Our experienced engineers are available to provide advice and support on any aspect of nail making, barbed wire making and chain link fence making needs. We believe that knowledge is power and are committed to helping you gain the skills you need to make sure your products meet the highest standards in the industry.

- At United Machinery, we understand that time is of the essence when it comes to manufacturing solutions. That’s why we are proud to offer a wide variety of services that can help you get the job done faster and more efficiently. Our team is dedicated to making sure you have the tools and resources necessary to increase your production rate and maximize your profits.

High Quality

With our superior quality, competitive price and professional service, we have gained great approval and satisfaction from customers globally.

Rich Experience

We have rich experiences for many nail making and wire making factories and helped a number of nail and wire making plants establish their own production lines in past years.

Complete Service

Sound service system, including pre-sale, mid-sale, and after-sale. We are committed to answering your request within 8 hours.

Quality Wire&Nail Machinery From China

We have become a trusted partner for many nail and wire factories over the years as we help them establish their own production lines. Our superior quality, competitive prices along with professional service has earned us great reviews from customers globally!

High Quality with Warranty

No Worries Service

Get Nail&Wire Machine Solution

By the latest advancements in nail making technology, we have created innovative solutions that have consistently increased customer satisfaction and loyalty over time. Our automatic nail making process is a testament to our commitment to delivering high-quality products and services to our clients.

Customer Site

Video

Number Speaks

Testimonials

Thank you for your help in providing a good wire making machine. We appreciate your assistance in making sure we got the best possible machine for our needs.

Jim Doe

Thank you for your excellent service. We have had a great experience with the machine and are very pleased with the results. Thank you again for your help and support.

Stefanie Willson

United Partners

Address:

119th,Rongyu Road , Xishan District,Wuxi City,Jiangsu Province,China

Email:

Mail:fysolution82@gmail.com

Open Hours:

Mon-Sat: 9am - 6pm

Why Choose Us?

- 1.Our professional design team offers customized services to cater to your unique needs and requirements.

- 2.Our production line is equipped with a strict control process to ensure the highest quality standards are met.

- 3.We employ fine processing technology to produce special nail and wire products.

- 4.Our products meet the electrical standards of different countries, ensuring compliance with local regulations.

- 5.We offer on-site installation, commissioning, training, maintenance, and other services to our customers for their convenience.

- 6.To ensure smooth operation upon delivery, we conduct a trial operation before shipping the goods to you.

- 7.Our remote video guidance service is available to assist our customers with any technical difficulties they may encounter.

- 8.We are committed to constantly improving the professionalism of our technical team to provide the latest technological advancements and enhance product performance for our customers’ benefit.

FAQ About United Machinery

- With over 25 years of experience in manufacturing wire drawing machines, nail making machines, and fence machines, United Machinery is well-equipped to handle the diverse requirements of different markets. We can adjust our equipment to meet the specific needs of each country, including electrical requirements, voltage, safety standards, and more. Our professional technical team and dedicated pre-sales and after-sales teams are committed to resolving customer issues and promoting safe and efficient production across various production lines. United Machinery prioritizes continual improvement and invests in enhancing the professionalism of our technical team to deliver the latest technological advancements and ensure optimal product performance for our customers’ benefit.

What are the advantages of united Machinery?

- United Machinery takes pride in leading a team with a strong service intent, open communication channels, and a customer-oriented approach to deliver customized solutions promptly. We support our clients every step of the way, from machine consultation, factory drawing, machine capacity analysis, machine on-line demonstration, to machine installation and commissioning. Our materials are sufficient, and we use internationally and China renowned brands for motors, electrical components, and reducers. United Machinery products are finely polished and painted, and customers can customize colors, logos, nameplates, etc. according to their requirements. Our machinery has passed ISO9001:2015 certification, and we take pride in being a noteworthy manufacturer, exporter, and supplier of wire and nail machinery for over 25 years.

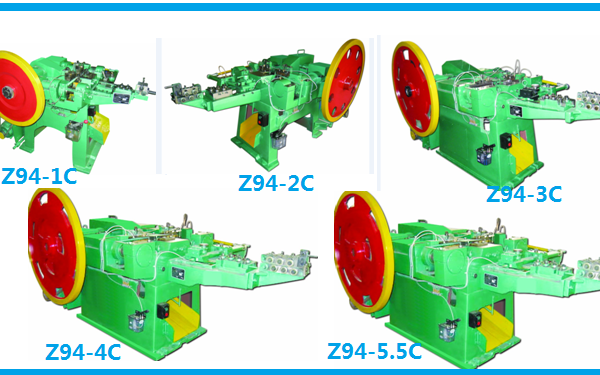

What Kinds of Nail making machines are available?

- There two main types of nail making machines: conventional (200-450pcs/min) and high-speed (600-750pcs/min).

- However, for specialized nails such as roofing nails, concrete nails, blind rivet nails, duplex nails, U-nails, and others, specific nail making machines are required to manufacture them accurately. Therefore, different types of nail making machines are recommended for making these types of nails.

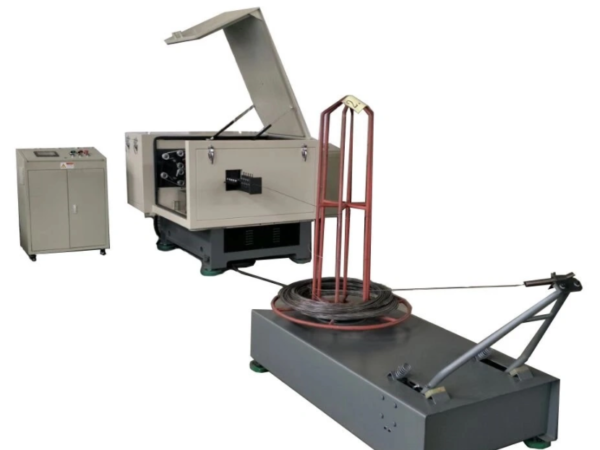

How many blocks of drawing machine we can choose to match the nail machine quantity?

- A complete nail making line typically begins with a wire drawing machine, which reduces the wire diameter from large to small. Our wire drawing machines are designed as a group-working type, with a different-sized wire drawing die on each block. As the wire passes through each wire drawing die on each drawing drum, the wire diameter is reduced.

- For example, a conventional wire drawing machine can reduce wire diameter from 6.5mm to 2.8mm, and by using six blocks of LW560 wire drawing machines, we can achieve around 5 tons per 8 hours. However, if only 1, 2, 3, 4, or 5 blocks are purchased as part of a production line, the capacity will be much lower.

- To achieve high capacity, we recommend using a straight-type wire drawing machine, which operates at 2-3 times the speed of a conventional wire drawing machine.It is ture that will need more budget for high capacity.

How to make barbed wire in different types?

- Barbed wire is an affordable fencing option that has sharp metal points, also known as barbs, to deter intruders. Our market offers three different types of barbed wire: double strand barbed wire (CS-A), single strand barbed wire (CS-B), and positive and negative twist barbed wire (CS-C). To make different types of barbed wire, you must choose a specific barbed wire making machine model that suits your needs. Each model can produce wire with different diameters.

- After the wire is made, barbs are added to make it extremely difficult to climb over. Barbed wire can be laid on the ground or mounted on top of fences to create a formidable barrier.

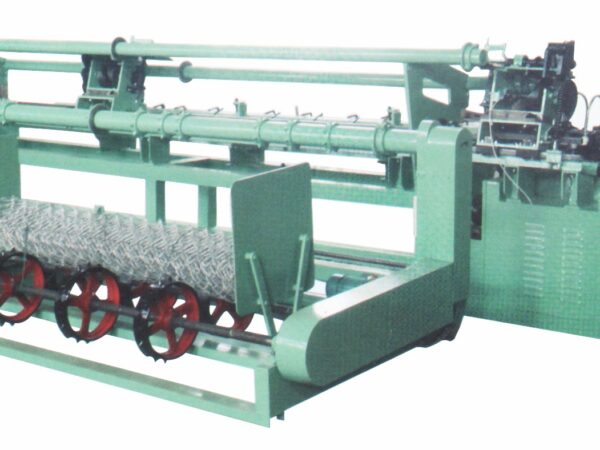

How do you make a chain link fence by our chain link fence machine?

- Chain link fence, also known as a diamond-mesh fence, wire netting fence, or hurricane fence, is a woven fence made of galvanized steel wires, PVC wires, aluminum-clad steel wires, etc.

- To make the chain link fence using our chain link fence machine, we must first confirm the wire mesh size that matches the same size mold on the machine and fix the mesh width length on the touch screen of the machine.

- Next, we load the coil wire onto the wire reel, which stays on both sides of the chain link fence machine. Then, we feed both wires into the machine’s straightening roller, which makes the wire straight and smooth, moving it into the mold and then into the wire netting pipe.

- Lastly, we turn on the start button after checking everything is in order, and one labor operates one machine. They can efficiently pack the mesh after the machine has netted the wire to the fixed length

What is the umbrella roofing nail ?How to make umbrella hea roofing nail ?

- Umbrella roofing nails are primarily used for installing roofing due to their large head, which distinguishes them from other types of nails. The galvanized appearance of these nails is usually much larger and flatter than other nails, allowing them to hold down roofing felt and shingles without causing any damage.

- Compared to wire nails, umbrella head roofing nails offer higher profit with less competition, although they require a experienced operator to produce.

- Umbrella roofing nails are composed of an umbrella head and a steel wire body. You can either purchase the umbrella roofing heads directly from the market or make them using a press machine. Buying the heads directly is usually cheaper, but selecting high-quality heads before feeding into machine. Once you have obtained the umbrella roofing heads, you can easily assemble them with the wire using a roofing nail making machine.

- Most roofing nails require galvanization to prevent rusting after making. We offer different capacity galvanizing machines that can be ordered to meet your specific needs.

- If you need a twist shank umbrella roofing nail,you will need wire twsiting machine when wire end drawing.

What after-sales service does United Machinery provide?

- United Machinery is committed to providing customers with comprehensive technical support services, even after the warranty period ends. Our technical staff will respond promptly to any customer feedback by email or phone to resolve issues and provide timely solutions.

- We also ensure that spare parts are replaced in a timely manner if they are found to be damaged during operation. Each machine comes with a recommended list of spare parts, which we advise customers to keep readily available to avoid any production interruptions. These may include nail molds, nail knives, punch pins, wire drawing dies, barbed wire cutters, fence machine molds, grinding wheels, and more.