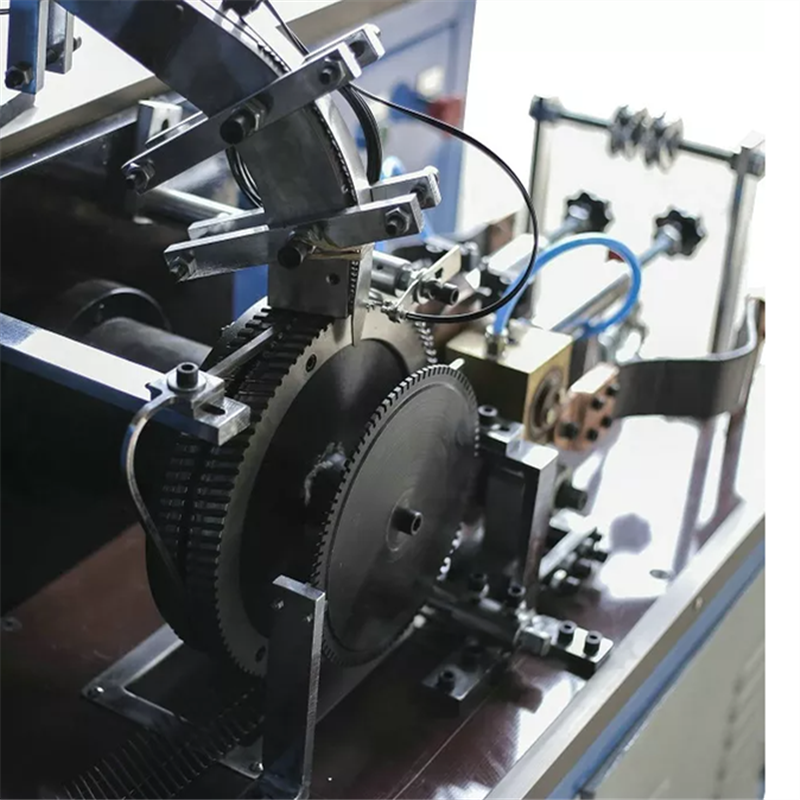

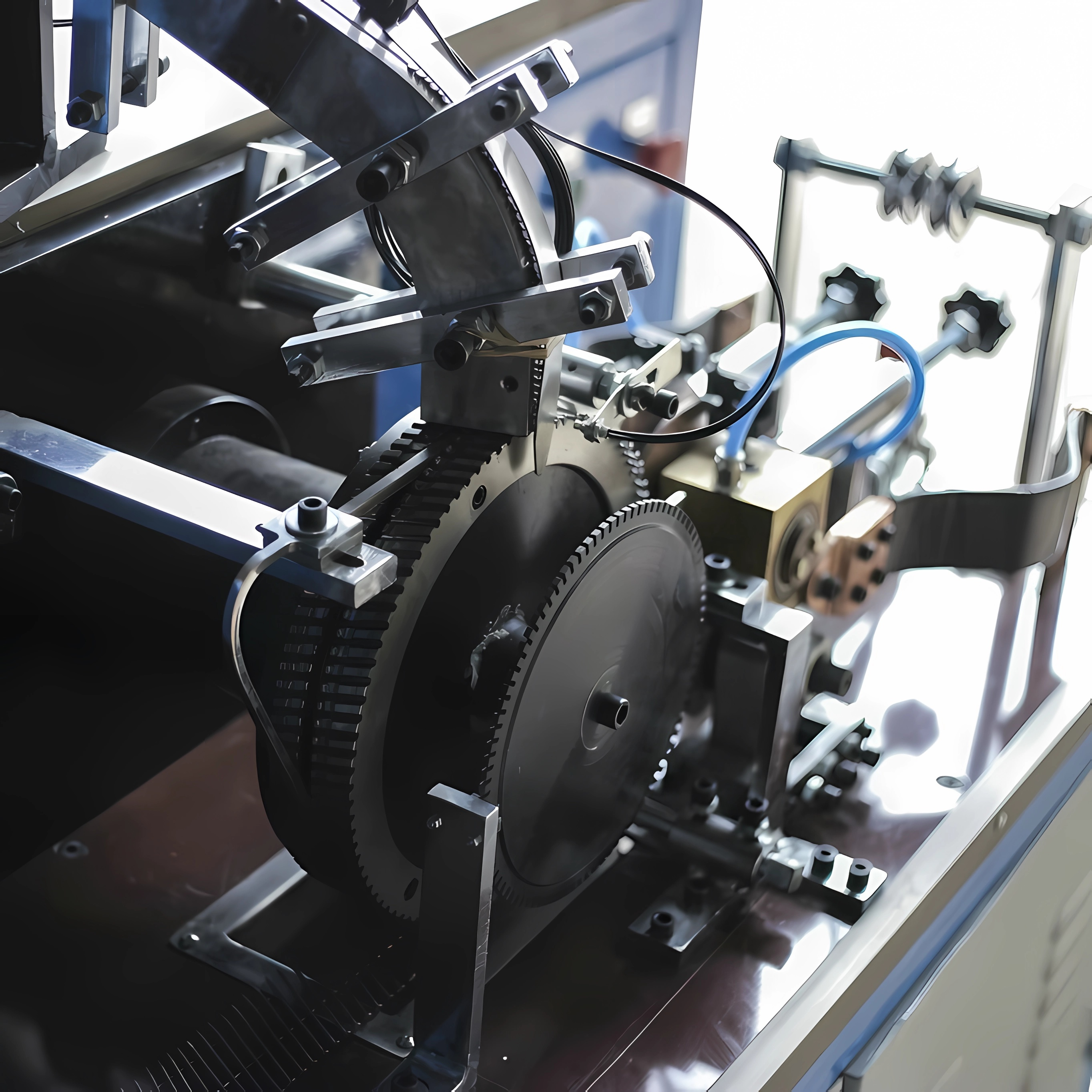

High Speed Coil Nail Collator

The High speed coil nail collator is a fully automatic high-frequency high-speed welding equipment. This machine used for regular coil nail and coil roofing nail making.Equip with PLC control ,screen touch setting control,high power welding, auto cutting,painting ,drying and collecting.

Specifications:

| Model THN-1 | |

| Range of Nail Dia.: | 1.8mm-4.1mm |

| Range of Nail Length: | 25mm-100mm |

| Output: | up to 2500pcs/min(length 25mm to 45mm). |

| Rated Power: | 8kw |

| Power of Nail Feeding System: | 0.75kw |

| Power of Welding System: | 20kw, 1000-2000A |

| Power Supply: | 3 phases AC 380V 50-60HZ |

| coil nail welding angle | 15/16degree |

| Head of diameter: | 9.3-9.9mm |

| coil nail welding wire diameter | 0.6/0.7/0.8mm |

| Packing: | packed in 2 wooden cases |

| Packing Size: | 3000X1500X1800mm |

| 2000×1200×800mm | |

| Weight: | 1600kg |

| Model THN-2 | |

| Range of Nail Cap Dia.: | 9.5mm-10.0mm |

| Range of Nail Dia.: | 1.6mm-4.1mm |

| Range of Nail Length: | 19mm-50mm |

| Output: | up to 1500pcs/min. |

| Rated Power: | 8kw |

| Power of Nail Feeding System: | 0.75kw |

| Power of Welding System: | 20kw, 1000-2000A |

| Power Supply: | 3 phases AC 380V 50-60HZ |

| Packing: | packed in 2 wooden cases |

| Packing Size: | 3000X1500X1800mm |

| 2000×1200×800mm | |

| Weight: | 1400kg |

Application:

- The High speed coil nail collator is a fully automatic high-frequency high-speed welding equipment. This machine used for regular coil nail and coil roofing nail making.Equip with PLC control ,screen touch setting control,high power welding, auto cutting,painting ,drying and collecting.

- During operation, the iron nails are placed in the feeding hopper and automatically unloaded. The iron nails are arranged in order by the vibrating plate, and then enter the nail wheel through the unloading track. The two copper-plated welding wires are welded into coiled nails, and then automatically dipped in paint to prevent rust and bake. Drying and counting are automatically rolled into rolls, and automatically cut according to the set count of each roll. The finished product can be packed into box by operator.

Machine Feature:

- Brand Electric part:Switch button — Schneider;Touch screen- MCGS;PLC, Frequency converter: OMRON

- High frequency weldingsysterm ,feature with high quality welding and improve the coil nail performance.

- Welding speed with 3300pcs/min which perfectly cover the machine collecting speed and full cover each welding spot.

- New developed automatic collecting systerm ,With this new systerm ,the finished collect nail could automaticall send to the stainless steel platform .And your people could pack the coil nail with higher efficiency.

- Wholeyear on line support,any technical problem or machine parts requirment ,we could support with 6 hours.

Products:

The high speed coil nail welding machine produced by our factoryis a fully automatic high-frequency high-speed welding equipment.

Our high-speed coil nail collator machine is a precision-engineered solution designed to efficiently coil finished nails. Our product features an innovative electronic control system, incorporating high grade electrical elements for optimal performance. Utilizing advanced inverter welding technology, this equipment offers superior power efficiency compared to similar models in the market. Unlike conventional methods of welding strength adjustment, our product employs welding frequency adjustment, ensuring stable and aesthetically pleasing coil nail welding. Furthermore, our coil nail collator boasts an extended lifespan, exceeding that of traditional models, while minimizing spark generation for enhanced safety.

During operation, the iron nails are placed in the feeding hopper and automatically unloaded. The iron nails are arranged in order by the vibrating plate, and then enter the nail wheel through the unloading track, and are welded into coiled nails by two copper-plated welding wires, and then automatically dipped in paint to prevent rust and bake.

Drying and counting are automatically rolled into rolls, and automatically cut according to the set count of each roll. The finished product can be produced by the operator after packing the finished product into the box.

1. What is the usage of high speed coil nail welding machine?

Our high-speed coil nail collator is versatile and compatible with a range of nails, including general steel nails and big cap nails. The flexibility of our equipment allows users to easily adjust the parameters of the coil nails to meet their specific requirements.

2. What is the advantage of the high speed coil nail welding machine?

All our electrical parts with 3 years warranty.

First our machine seamlessly integrates an Omron programmable logic controller, renowned for its precision and reliability, ensuring optimal performance. Complementing this advanced control system is the inclusion of a sleek touch display branded MCGS, offering intuitive and user-friendly operation.

But what truly sets this machine apart is its utilization of high-quality components from distinguished brands. The long-life potentiometers, proudly bearing the Japan TOCOS brand, guarantee exceptional durability and accuracy throughout the machine’s lifespan. The sensors, meticulously crafted and branded Korea Horta Knicks, exhibit unrivaled sensitivity, ensuring precise detection and measurement. To facilitate smooth and efficient operation, the machine incorporates small motor reducers branded Taiwan OPG, renowned for their superior performance and longevity.

In addition, the relays, carrying the esteemed Yan Ling brand, provide robust electrical control, effectively managing power distribution within the machine. The inclusion of isolated regulators enhances stability and safeguards against potential electrical fluctuations, further solidifying the machine’s reliability.

With these exceptional components working in perfect harmony, the Automatic Coil Nail Making Machine consistently delivers outstanding performance, operating flawlessly to produce high-quality coil nails. Whether it’s the precision of each nail’s dimensions or the flawless finish that meets industry standards, this machine surpasses expectations with every production cycle.

3.How to ensure proper nail welding with this machine?

(1)The coil nail machine features a high-frequency welding power source with an adjustable frequency range of 20,000 to 40,000 Hz. This high-frequency welding ensures that each nail undergoes at least 10 complete welding waveforms, guaranteeing reliable and high-quality tack welding. Additionally, this feature reduces the need for external adjustments, enhancing efficiency.

(2)The welding transformer in the machine utilizes advanced nano-magnetic amorphous technology, resulting in a smaller size and significantly reduced heat loss. Under similar working conditions, this transformer enables more than 30% energy savings during the welding process.

(3)The machine incorporates a robust elbow structure made from thick stainless steel to enhance durability. This design effectively reduces the occurrence of nails getting stuck, ensuring smoother operation and a longer lifespan.

- The machine is equipped with a raised rail structure, making it easy to remove staples. This feature simplifies maintenance and ensures seamless operation, saving time and effort.

4.How to choose the copper welding wire when coil nail production?

The coil nail welding wire is an essential consumable material used throughout the entire coil nail production line. It is made of low carbon steel wire that undergoes heat treatment and is coated with a layer of copper. These welding wires are primarily used to manufacture various types of coil nails.

Features:

Wire Type: Can be neutral or customized according to specific requirements.

Surface Treatment: Copper Coated for enhanced durability and corrosion resistance.

Diameter Sizes: Available in 0.60 mm, 0.65 mm, 0.70 mm, and 0.80 mm to suit different nail production needs.

Packing Size: Each spool contains either 16Kgs or 18Kgs of welding wire, providing sufficient supply for efficient production.

Elongation: Offers a 15-20% elongation rate, ensuring flexibility and strength in the welds.

5. How to feed the nail into machine?

We offer a comprehensive range of high-speed coil nail welding machines, complete with a nail feeder and hopper. This setup ensures a seamless workflow, as the nails are loaded into the hopper, passed through the feeder, and eventually dropped into the machine vibrator.

In addition to the welding machine, we also provide an Electromagnetic nail grabbing equipment. This innovative device can be conveniently attached to the machine feeder every 5-10 months to automatically fix a few nails. By automating this task, it simplifies the operation of the machine and enhances the overall efficiency of the nail production process, resulting in a smoother workflow.

Our aim is to provide user-friendly solutions that optimize productivity and streamline operations.

Please note that specific details and customization options are available upon request.