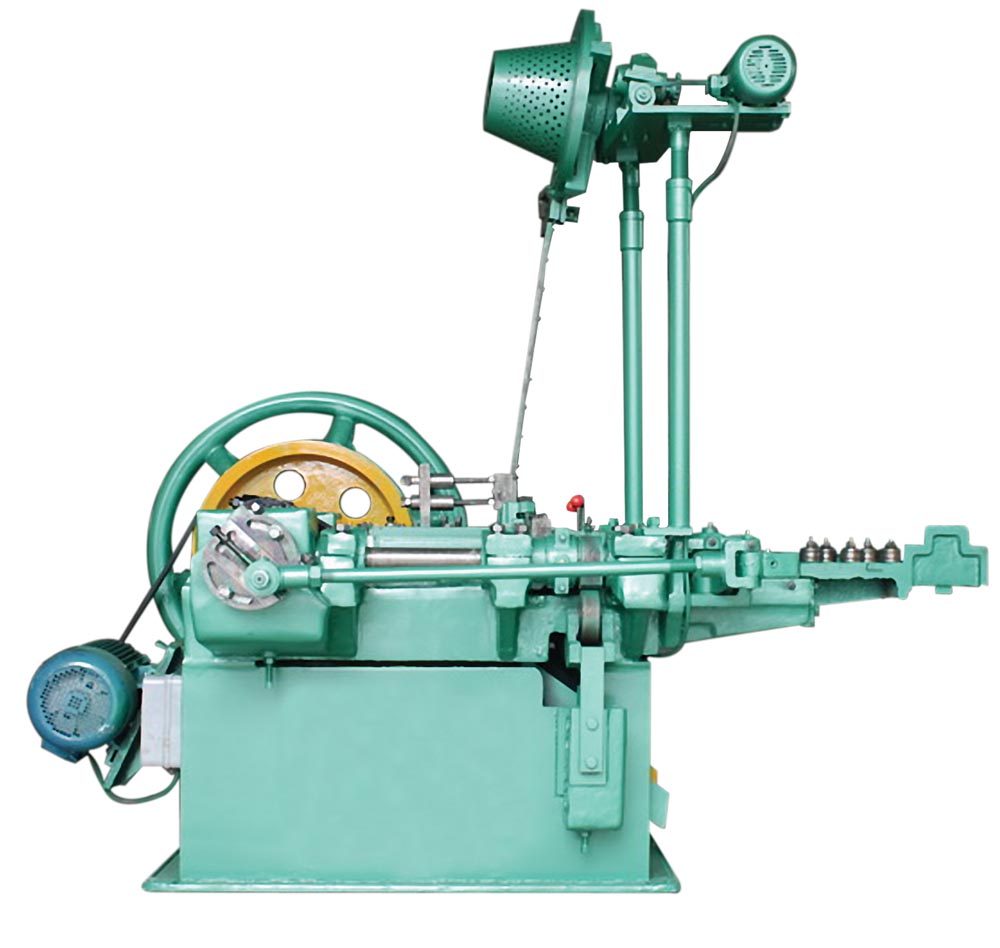

Automatic Roofing Nail Making Machine

Automatic Steel Roofing Nail Making Machine can manufacture both general and twist roofing nail of various sizes.The turn plate rolling feeder will automatically transport the umbrella head one by one though the vertical channel into the working center.Then the roofing nail will automatically form once we start the equipment with steel wire feeding.After assembled,the nail will automatically sent out.

Specifications:

| Parameter | Unit | WZ94-4C |

| Dia of nail max | mm | 3.8 |

| Dia of nail min | mm | 2.38 |

| Length of nail max | mm | 100 |

| Length of nail min | mm | 50 |

| Designed output | pcs/min | 130-150 |

| Motor power | kw | 4 |

| Speed | rotate/min | 960 |

| Weight(approx) | kg | 2100 |

| Overall dimensions | mm | 2436X1512X1710 |

Video:

Application:

- Automatic Steel Roofing Nail Making Machine can manufacture both general and twist roofing nail of various sizes.The turn plate rolling feeder will automatically transport the umbrella head one by one though the vertical channel into the working center.Then the roofing nail will automatically form once we start the equipment with steel wire feeding.After assembled,the nail will automatically sent out.

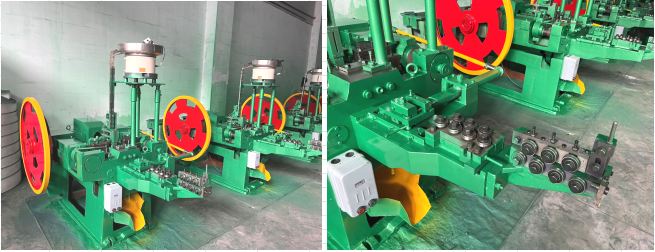

- For Africa market ,We develope another vibrating hopper roofing nail head feeding system,This system feature stable feeding ,easy operating and effective maintain. It could be the best choise for new operator.

Machine Feature:

- key components (crankshaft,cramConnecting rod,gear,side shaft) are made of high-grade steellike 40cr,45#steel casting ,45#steel forging ect.

- Machinewith plunger structure make the nail making with few impact ,nice forming and with small power consumption.

- Length can adjust on each model machine,Diameter different by change the nail mould.

- Machine developed with less spare part which make the operating easier and maintain friendly .

- Each machine strictly inspect and well packed before shipping.As soon as machine arrived,you can fix on the concrete ground and start working at once.

- Machine install and commision service available .

- Wholeyear on line support,any technical problem or machine parts requirment ,we could support with 6 hours.

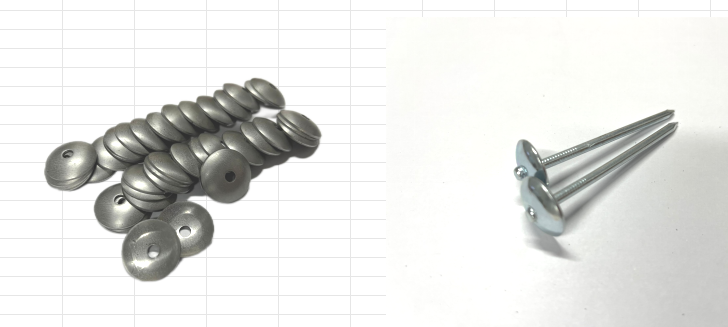

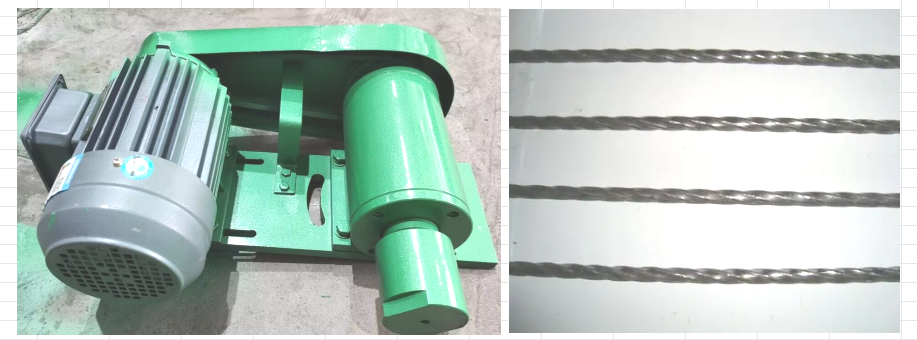

Finished Products:

The study about the roofing nail making process:

Q:What does the roofing nail consist of ?

A:A roofing nail is made up of two main components: the roofing head cap and the steel wire shank. The roofing nail cap is typically manufactured using iron with a thickness of 0.9mm-1mm and an outer diameter of 15mm-20mm. The middle steel shank usually has a popular diameter range of 2.5mm-4.2mm (BWG8, BWG9, BWG10, BWG11, BWG12, BWG13).

Q:What does our roofing nail making machine do?

A:Our roofing nail making machine is equipped with a vibrator on the top, which securely holds the iron cap in place. Additionally, there is a wire pay off system that holds the steel wire in front of the machine. The wire is fed into a wire straight rolling mechanism, which straightens and guides it into the working center of the roofing nail making machine.

Once the machine is started, the iron cap is automatically dropped into the working center where it is perfectly assembled with the feeding steel wire using a machine mold grip. The nail cutter then cuts the tip, and the punch pin punches the roofing nail head. This machine operates at a speed of up to 150 pieces per minute, increasing efficiency and productivity.

With proper training, a single worker can produce approximately 500-800 kilograms of roofing nails per day .

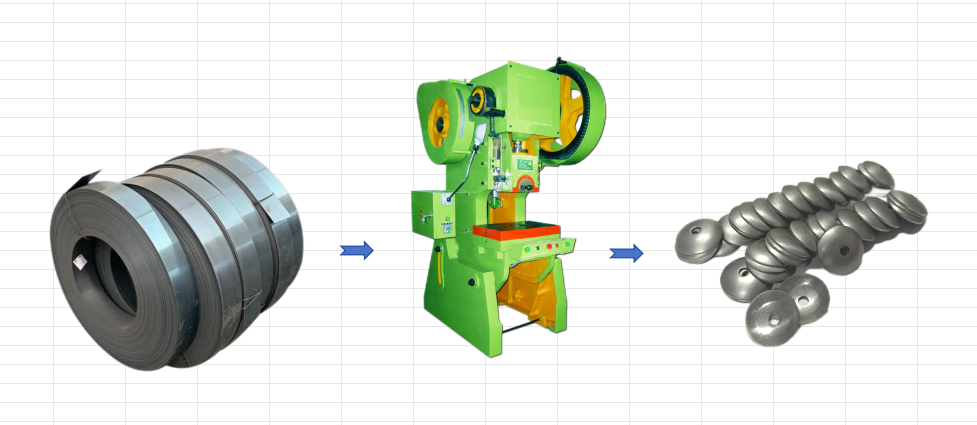

Q:How to get the roofing nail cap?

A:The roofing nail cap can be obtained directly from the Chinese market or manufactured using a cap press machine. Here are some tips for both options:

Buying from the market: Roofing nail caps available in the market are often made from recycled iron sheets, making them cost-effective. However, it is important to have skilled workers who can properly handle these caps before feeding them into the roofing nail making machine.

Roofing nail cap press machine: This machine produces uniform roofing nail caps using iron sheet coils as the material. Although this option may be more expensive than buying from the market, it offers easier operation for workers during the roofing nail manufacturing process. The use of uniform caps ensures smoother production with fewer interruptions.

Q:how to make the twist roofing nail?

A:The twist roofing nail requires the use of twist wire during the nail-making process. This twist wire is typically obtained by using a wire drawing machine that is equipped with a twisting tool on its last drum.

Q:How to make the galvanized roofing nail?

A:As soon as the roofing nail well formed by the roofing nail making machine,we will send the finished nail to do the galvanizing process.

- The Nail Galvanized machine for roofing nail galvanized can be order to make according to the capacity.we have capacity with 200kg per hour up to 1000kg per hour.It is a process of forming uniform, dense, combined with good metal or alloy deposited layer on workpieces surface after the effect of electrolysis.

- Compared with other metals, zinc is relatively cheap and easy plated metal, and also is a low corrosion plating layer, which is widely used to protect steel parts, in particular to prevent atmospheric corrosion, as well as used for decoration filed.

- Electric galvanized plating machine technical processes:

Chemical degreasing → Water rinse → Electric galvanized zinic → Rinse → Passivation →Rinse →Hot Water rinse → Rinse → drying