Blind Rivet Making Machine

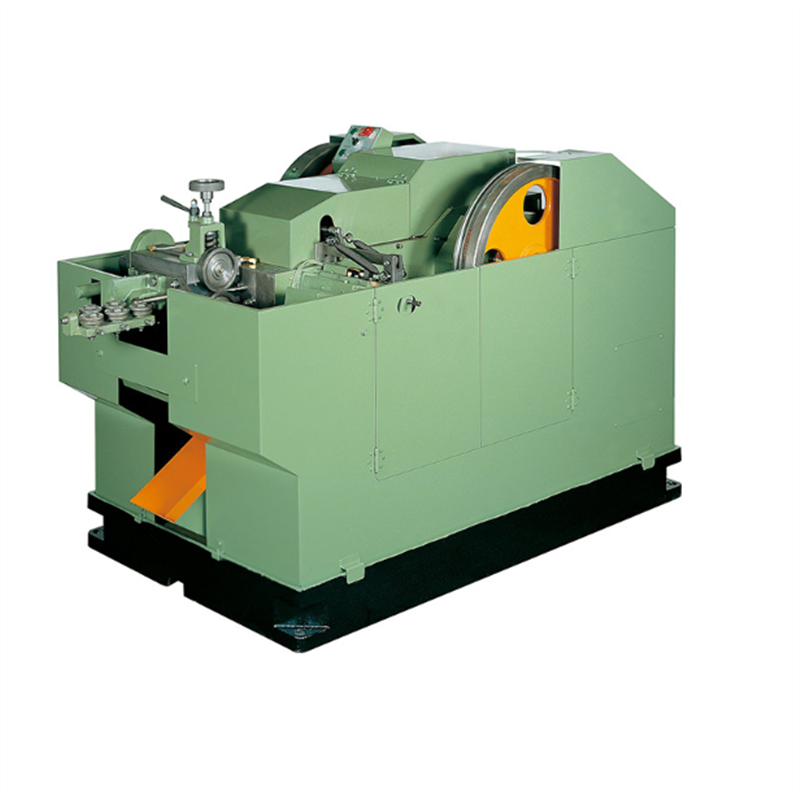

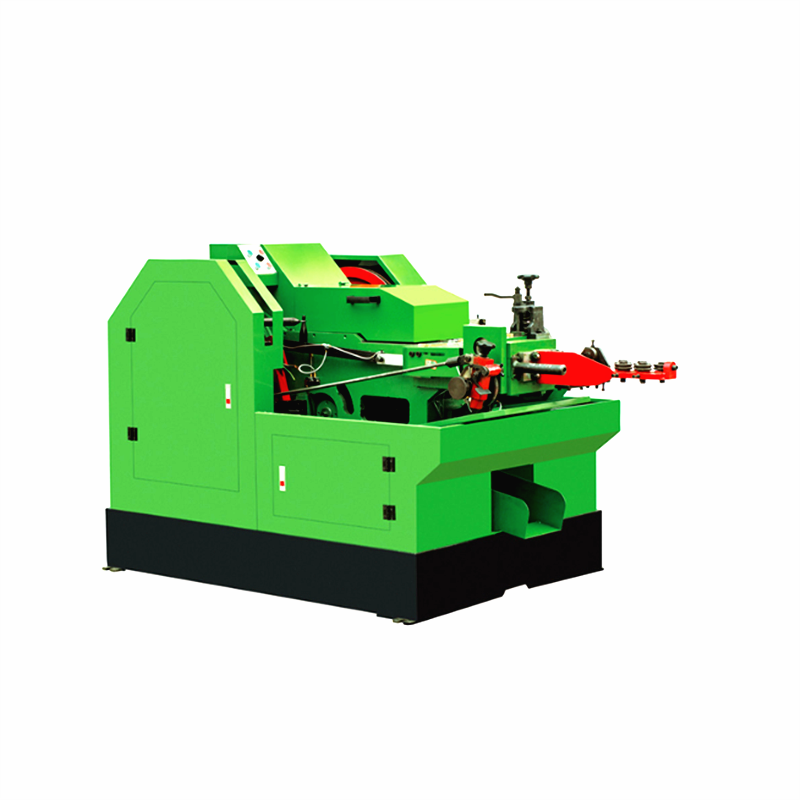

1.Cold Heading Machine

- This machine mainly used for forming the head of the blind rivet, the work principle is line materials calibration, accessing lines, sending materials to the main mold, first punching initial forging, and second punching the formed blank materials and withdraw.

- Blind rivet head forming machine operates smoothy with low noise generation,Thus improving the working environment.Moreover,It can make high qualified rivet aluminum cap with less raw material,thus lowering the cost.

| Model | Max. Blank Diameter/mm | Max. Blank Length/mm | Strike | Capacity pcs/min | Body Motor Power /KW | Oil pump Power/KW | Volume(L*W*H)/m | Weight/kg |

| UL4-20B | Ф4.0 | 20 | 68 | 80-120 | 2.2 | 0.18 | 1.75×0.85×1.15 | 1300 |

| UL5-30B | Ф5.0 | 30 | 92 | 80-110 | 3 | 0.18 | 2.3×1.08×1.15 | 1700 |

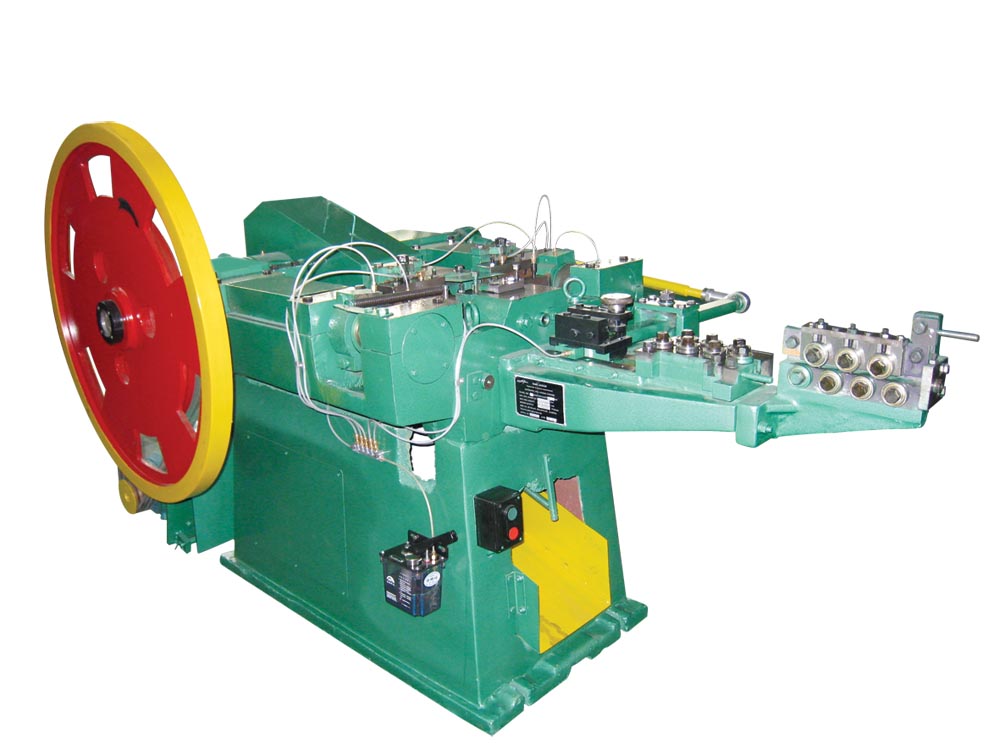

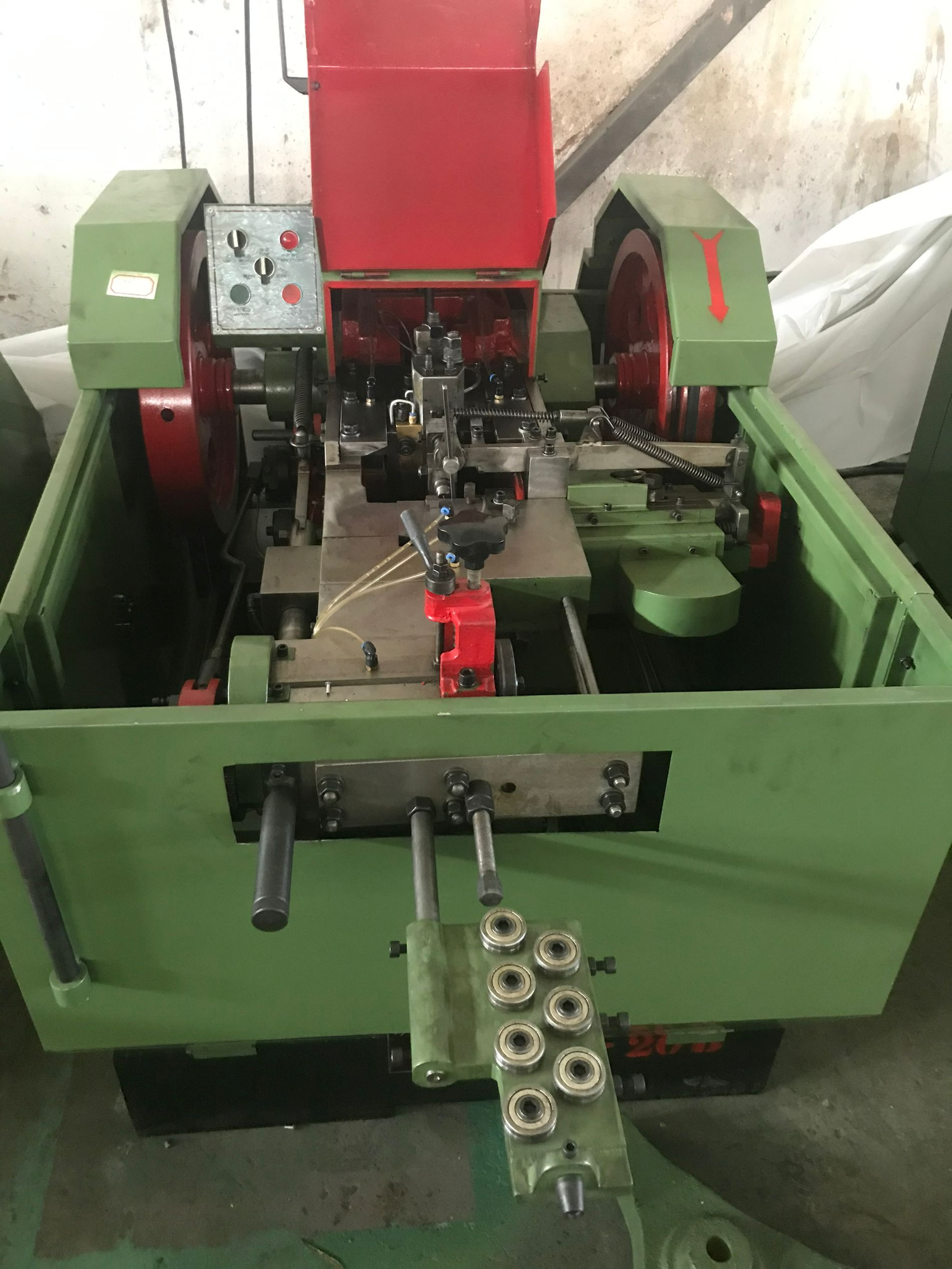

2. Nail Making Machine

- Z94-3C nail making machine is specially used for blind rivet nail making after fixing special nail mould,nail cutter and punch pin ,The wire could automatically feeding to machine working center and one-set moulded into the desired product.

| Model | unit | Z94-3C |

| Dia of nail max | mm | 3.4 |

| Dia of nail min | mm | 1.8 |

| Length of nail max | mm | 80 |

| Length of nail min | mm | 30 |

| Dsigned out put | pcs/min | 320 |

| Moter power | kw | 3 |

| Weight(approx) | kg | 1400 |

| Overall dimensions | mm | 2000x1400x1400 |

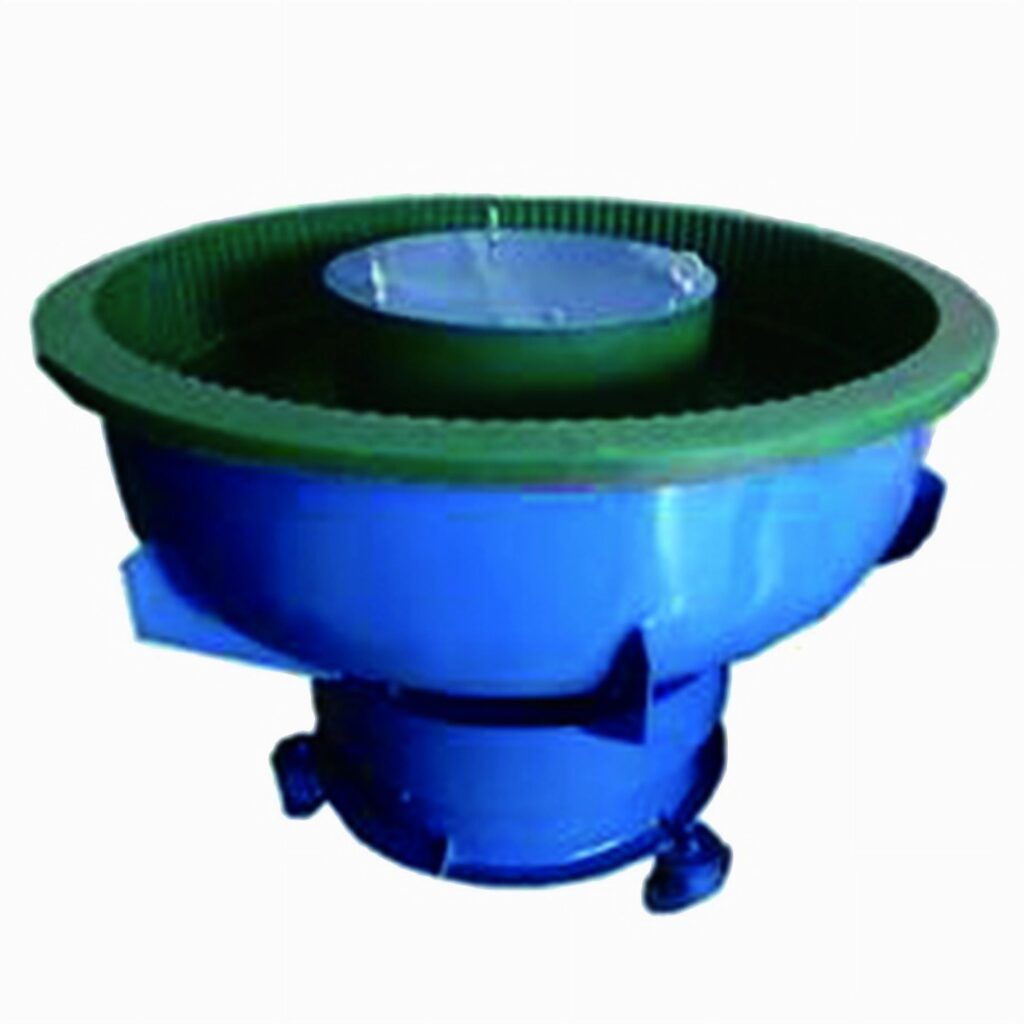

3.Vibratory polish machine

- This Vibratory polish machine widely used for different kind workpieces,such like rivet,bicyle parts and so on.

- Suitble material:Aluminum,copper,Aluminum alloy,Iron,Zinc alloy ect.

| Model | Volume L | Weight Kg | Motor Power Kw | Overall dimensions mm | Fill Volume L |

| UM-D50 | 50 | 260 | 1.1 | φ730*715H | 150 |

| UM-D100 | 100 | 360 | 2.25 | φ94*860H | 300 |

4.Drying machine

This machine used for dry the blind rivet hat after polish blind rivet head.

| Model | Unit | UM -500 DRYING MACHINE | |

| Inner Barrel size | mm | φ 500*400 H | |

| Mesh size of barrel | mm | 4 | |

| dryer motor | kw | 1.1 | |

| Heating motor | kw | 3 | |

| Machine weight | kg | 200 | |

| Machine diamension | mm | 800*1000*850 | |

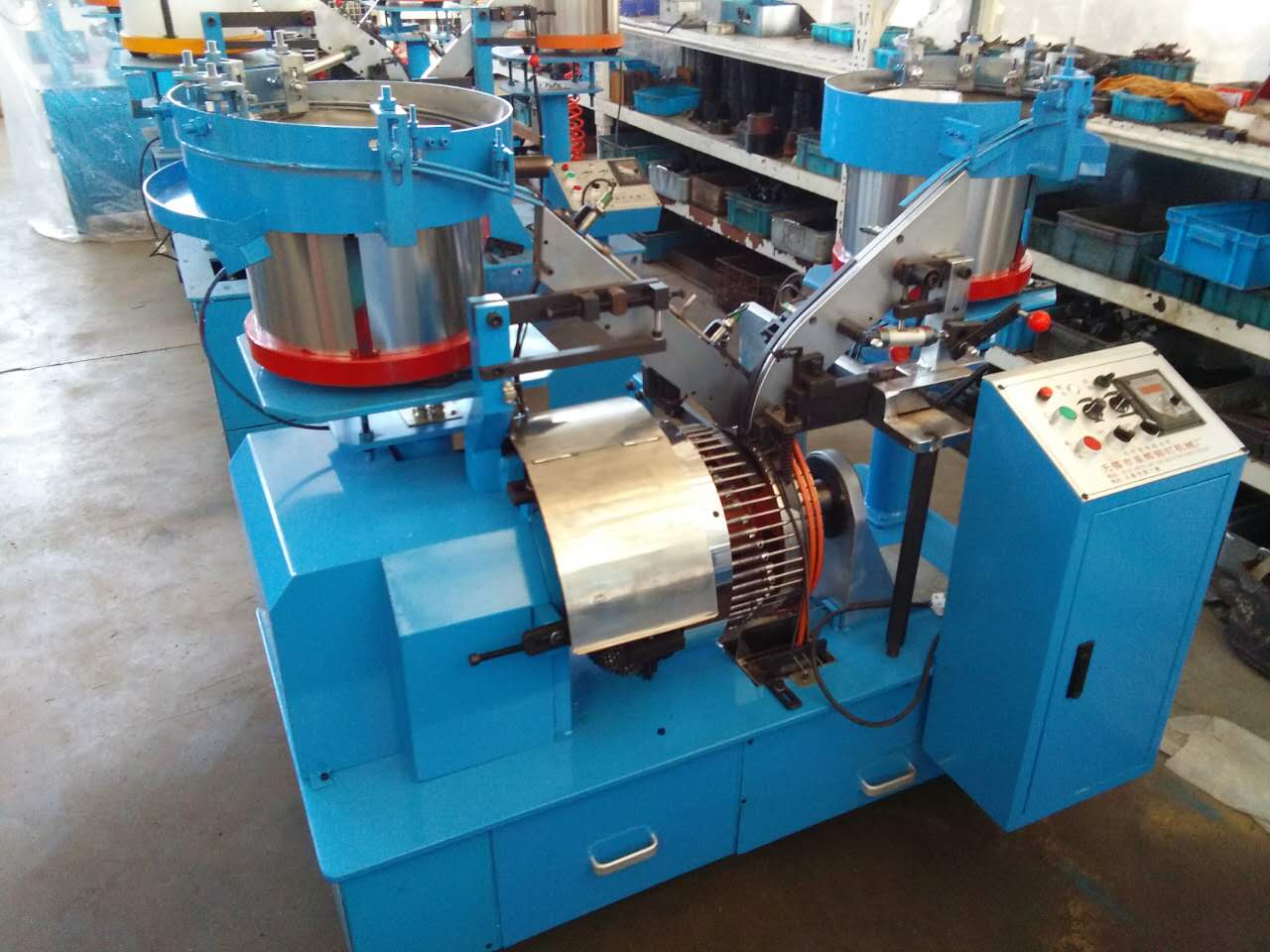

5.Assembly machine

- Our assembly machine is designed for automatic assembly different size blind rivet head and nail .The assembly speed could be adjust according to the rivet length by the variable frequency inverter.

- Machine equip with torque protection device. when the twisting force exceeds an applicable limit, the clutch automatically skid, and 5 seconds later the machine stops.This safety device can ensure of the operator and the machine.

| Model | Unit | UM-3 Assembly machine | |

| Assembly Diameter | mm | 2.7-6 | |

| Assembly rivet length | mm | 4-30 | |

| power: | 0.75kw AC220V | ||

| Capacity: | pcs/min | 500-600 | |

| Machine weight | KG | 500 | |

| Diamension | mm | 1600*750*1700mm | |

Q:What is the material for the blind rivet?

A:The material of a blind rivet can vary depending on the specific application and requirements. Blind rivets, also known as pop rivets, are typically made from materials such as aluminum, steel, stainless steel, or brass. Each material has its own set of advantages and characteristics that make it suitable for different applications. For example, aluminum blind rivets are lightweight and corrosion-resistant, making them ideal for applications where weight is a concern or when joining aluminum materials. Steel blind rivets are known for their strength and durability, making them suitable for heavy-duty applications. Stainless steel blind rivets offer excellent corrosion resistance, making them suitable for outdoor or marine applications. It’s important to choose the right material based on the specific needs of your project

Q:How to make the blind rivet?

A:To produce a blind rivet, the general process involves the following steps: Material Selection: Choose the appropriate material for the blind rivet based on the application requirements. For example the popular we make are aluminum body and steel mandrel .we could prepare the aluminum wire and steel wire as raw material.

Rivet Body Production: The manufacturing process of the rivet body involves utilizing a cold-heading machine. During this process, an aluminum wire is fed into the working center of the cold heading machine. The wire is then gripped by the mould, punched, and cut to form the desired shape. As a result, a rivet body with a head and a hollow cylindrical body is produced.

Mandrel Production: The mandrel is the central shaft of the blind rivet that gets pulled during installation to create a secure joint. The mandrel can be made from a different material than the rivet body, often steel or stainless steel.

Assembly: The mandrel is inserted into the hollow rivet body, and the two components are joined together. This assembly can be done using automated machinery or manual processes.

Q:Will the steel mandrel part of blind rivet need to be galvanized?

Most of the blind rivet sample we get is galvanized one.So for this galvanized process,we will need nail galvanized machine(electroplating machine)

As soon as the steel mandel part well formed by the nail making machine,we will send the finished nail to do the galvanizing process.

- The Nail Galvanized machine for nail galvanized can be order to make according to the capacity.we have capacity with 200kg per hour up to 1000kg per hour.It is a process of forming uniform, dense, combined with good metal or alloy deposited layer on workpieces surface after the effect of electrolysis.

- Compared with other metals, zinc is relatively cheap and easy plated metal, and also is a low corrosion plating layer, which is widely used to protect steel parts, in particular to prevent atmospheric corrosion, as well as used for decoration filed.

- Electric galvanized plating machine technical processes:

Chemical degreasing → Water rinse → Electric galvanized zinic → Rinse → Passivation →Rinse →Hot Water rinse → Rinse → drying