Barbed Wire Making Machine

- Our factory can provide a most development barbed wire making machine which can used for double strand barbed wire making (CS-A), single strand barbed wire making (CS-B), Positive and negative twist barbed wire making (CS-C).

- This machine has the advantages of safety operation, stable action, low noise and energy saving, advanced electronic counting.

Specifications:

| No. | Description | Unit | CS-A barbed wire machine | CS-B barbed wire machine | CS-C barbed wire machine |

| 1 | Motor | kw | 2.2 | 2.2 | 2.2 |

| 2 | Main drive shaft speed | r/min | 402 | 355 | 355 |

| 3 | Unit wire diameter | mm | 2.2-3.0 | 2.2-3.0 | 1.6-2.8 |

| 4 | Barbed wire diameter | mm | 1.8-2.2 | 1.8-2.2 | 1.6-2.2 |

| 5 | Barbed pich | inch | 3,4,5 | 4,5 | 4,5 |

| 6 | Twist Number | pcs | 3.5 | 3.5 | 7 |

| 7 | Theoretical capaticy | Kg/h | 70 | 40 | 40 |

| 8 | Total weight | kg | 1200 | 1000 | 1000 |

| 9 | Dimension of main part | mm | 2000*1500*1500 | 3100*1130*1500 | 3000*1000*1150 |

Video:

Application:

- Our factory can provide a most development barbed wire making machine which can used for double strand barbed wire making (CS-A), single strand barbed wire making (CS-B), Positive and negative twist barbed wire making (CS-C).

- This machine has the advantages of safety operation, stable action, low noise and energy saving, advanced electronic counting.

- The products produced by this machine are widely used to construct inexpensive fences and walls like railways, highways, farming and animal husbandry.

Machine Feature:

- The screw thread system has the advantages of simple structure, convenient operation and easy adjust according to our demonstration video.

- Take up reel can be customized according to customer requirements.

- offer a high level of operator safety while maximizing production rates and efficiencies for barbed wire

- Auto counter systerm and easy to calculate the barbed wire length.

- Steel cover for safe protection.

Finished Products:

Babed wire making machine–the simple guide

Barbed wire making machines are essential and highly important in the construction industry. They play a crucial role in providing security and protection for construction sites, storage areas, warehouses, and other industrial facilities. Here are some key points to give you more idea about our barbed wire making machines.

Q:What is the material for making barbed wire?

A.Usually the materials used are general hot-dip galvanized low-carbon steel wire and low-strength steel wire .

Q:What is the application of the barbed wire making machine?

A:Barbed wire machine is used to produce barbed wire, which is widely used for safety protection function, national defense, animal husbandry, playground fence, agriculture,railways,highways,expressway, etc.

Q:What kind barbed wire of our barbed wire making machine can make?

A:Our factory can provide a most development barbed wire making machine which can used for double strand barbed wire making (CS-A), single strand barbed wire making (CS-B), Positive and negative twist barbed wire making (CS-C)

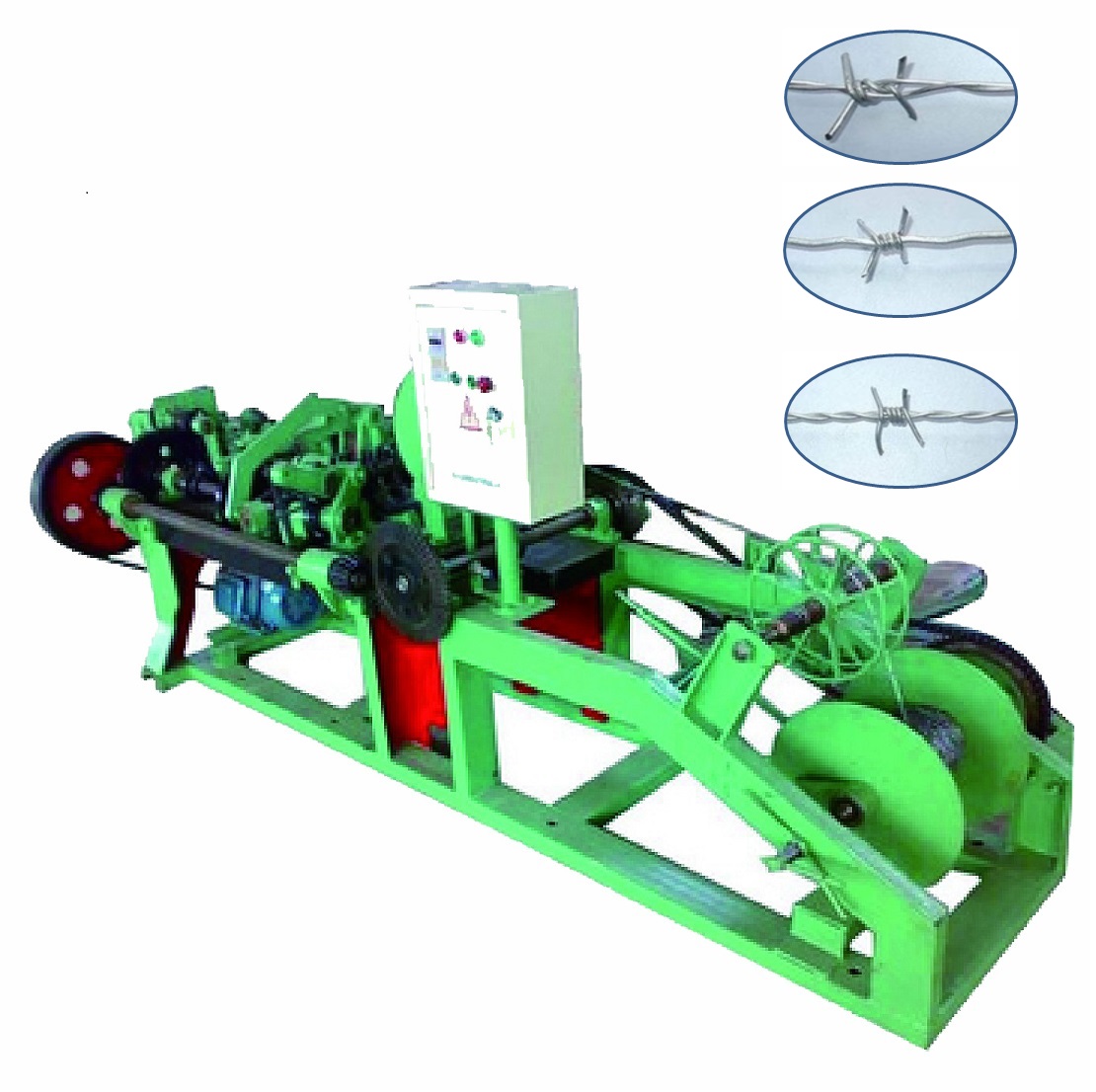

Photo for double strand barbed wire making machine and the barbed wire sample (CS-A)

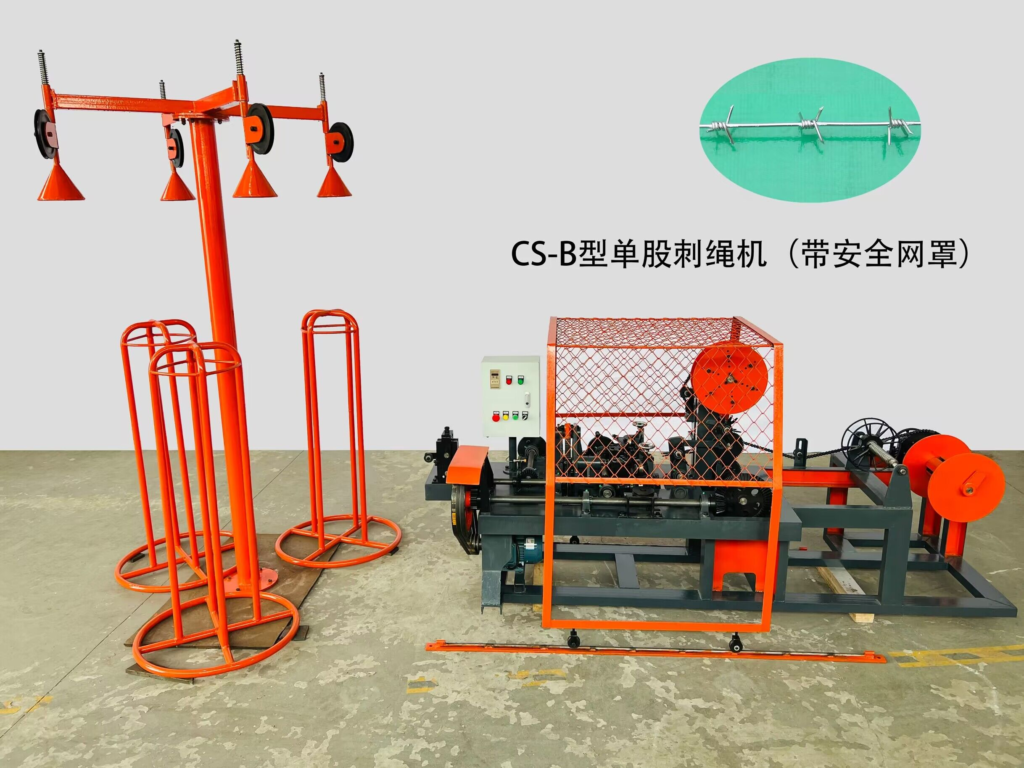

Photo for single strand barbed wire making machine and the barbed wire sample (CS-B)

Photo for Positive and negative twist barbed wire making machine and the barbed wire sample(CS-C)

Q:What are the key considerations when installing a barbed wire making machine?

- Securely fix the frame and base of the barbed wire makingmachine to prevent any movement or vibration during operation. The barbed wire machine has 8 anchor bolt holes, with 3 of them needing to be drilled underground. These holes should be 350mm deep and match the size of the machine. When pouring the cement, it is important to ensure there is no leakage.

- Ensure that all electrical connections meet local safety regulations.

- Install guardrails and guards around the machine to prevent any operator from accidentally coming into contact with moving parts.

- Ensure that the barbed wire making machine is correctly calibrated according to manufacturer’s specifications.

- The alignment of the main gear and auxiliary gear must allow for a certain gap between their teeth, ensuring that they are not completely occluded. This is necessary because the machine requires a level of resistance, and having some relaxation while running is beneficial.

Q:Why Wuxi United machinery is Your Best Bet For barbed wire making solution?

Wuxi United Machinery is widely regarded as a leading provider of barbed wire making solutions, thanks to their cutting-edge technology and extensive expertise in wire drawing machine, nail making machine, barbed wire making machine, and chain link fence making machine. They are known for their automated processes that ensure efficient and high-quality machine production. Wuxi United Machinery offers a range of nail making machines, including the dependable Z94 model, which boasts features such as high speed, low noise, minimal impact, and exceptional accuracy.

One notable aspect of Wuxi United Machinery is their wealth of experience in handling nail making projects of various scales in different countries. They have the knowledge and capabilities to assist you throughout the entire process, from designing a complete production line to providing support until the machines are successfully commissioned in your workshop. Their expertise and customer-centric approach make them a reliable choice for your nail making needs.