High Speed Nail Making Machine

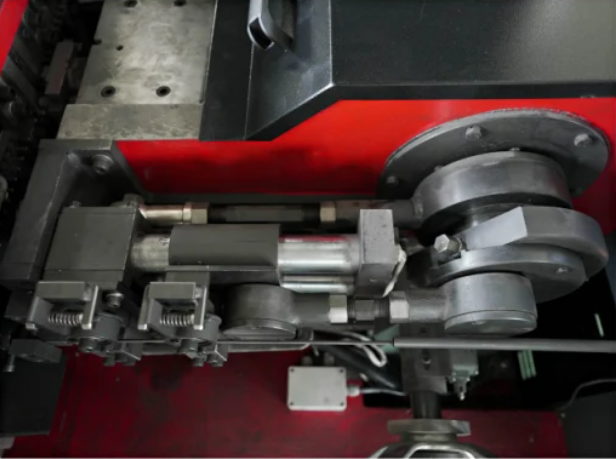

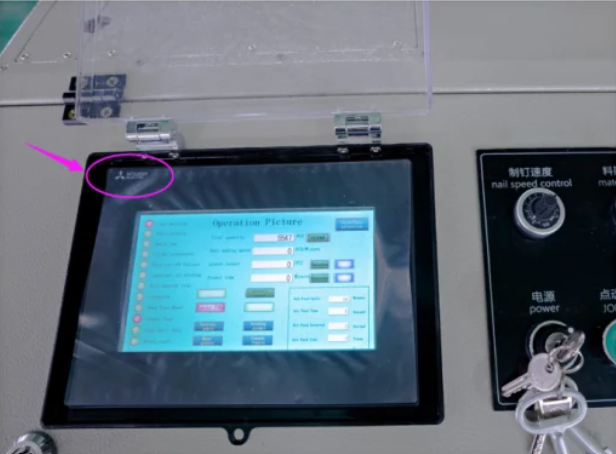

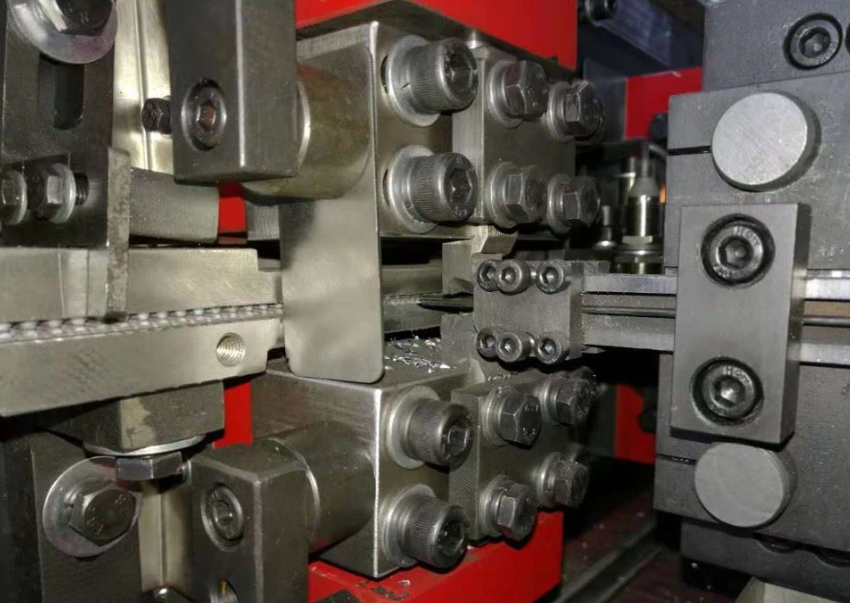

Our high speed low noise automatic nail making machine is featured with faster speed,quiet working and precise nail size making.It is with fully automatic and controlled by frequency converter on feeding the material and manufacturing nail, which can adjust the speed according to different kind diameter and different type material.

Specifications:

| Nail Details | Nail length range | MM | 70-150 |

| Nail making speed | pcs/min | 520-700 | |

| Nail diameter range | MM | 2.5-5.0 | |

| Main machine | Main machine power | KW | 8.5 |

| Pay-off power | KW | 1.5 | |

| Actual total power | KW | 4 | |

| Machine dimension | Main machine dimension | MM | 1650x1200x1300 |

| Pay-off dimension | MM | 1500x800x350 | |

| Electric box dimension | MM | 400x600x800 |

| Nail Details | Nail length range | MM | 50-130 |

| Nail making speed | pcs/min | 520-700 | |

| Nail diameter range | MM | 2.5-3.5 | |

| Main machine | Main machine power | KW | 8.5 |

| Pay-off power | KW | 1.5 | |

| Actual total power | KW | 4 | |

| Machine dimension | Main machine dimension | MM | 1500x1300x1300 |

| Pay-off dimension | MM | 1500x800x350 | |

| Electric box dimension | MM | 400x600x800 |

| Nail Details | Nail length range | MM | 45-90 |

| Nail making speed | pcs/min | MAX760 | |

| Nail diameter range | MM | 2.0-3.5 | |

| Main machine | Main machine power | KW | 5.5 |

| Pay-off power | KW | 1.5 | |

| Actual total power | KW | 4 | |

| Machine dimension | Main machine dimension | MM | 1400x1200x1100 |

| Pay-off dimension | MM | 1500x800x350 | |

| Electric box dimension | MM | 400x600x800 |

| Nail Details | Nail length range | MM | 32-50 |

| Nail making speed | pcs/min | Max800 | |

| Nail diameter range | MM | 2.0-3.0mm | |

| Main machine | Main machine power | KW | 5.5 |

| Pay-off power | KW | 1.5 | |

| Actual total power | KW | 4 | |

| Machine dimension | Main machine dimension | MM | 1350x900x1260 |

| Pay-off dimension | MM | 1500x800x350 | |

| Electric box dimension | MM | 400x600x800 |

Video:

Application:

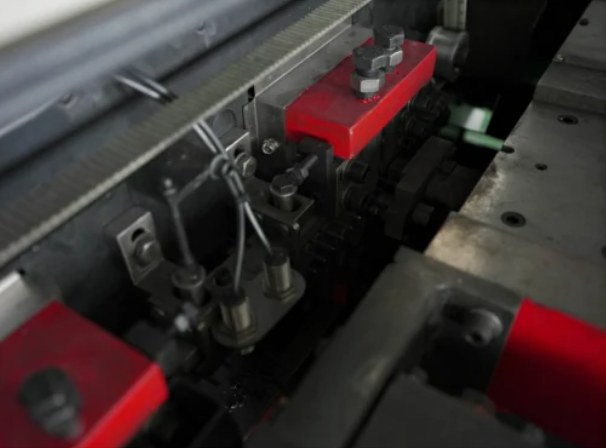

Wuxi United Machinery Nail manufacturing machine are the most efficient in our marcket.Our high speed low noise automatic nail making machine is featured with faster speed,quiet working and precise nail size making.- It is with fully automatic and controlled by frequency inverter on feeding the material and manufacturing nail, which can adjust the speed according to different kind diameter and different type material.

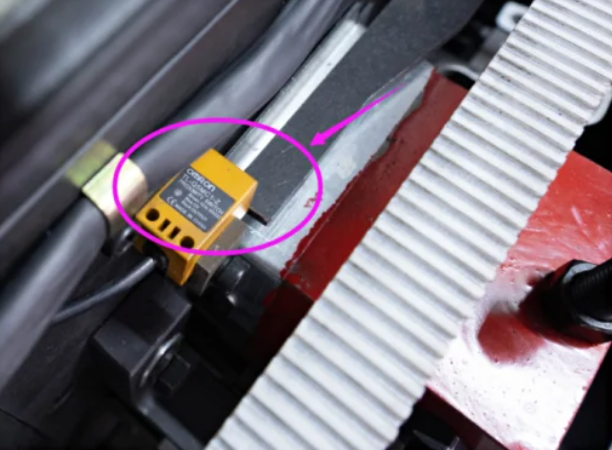

- It is with fully automatic which can auto-stop and alarm when the machine is failed in material feeding,material jam,out-tolerance on lendth,lacking of lubricate,over-loading and so on.

- Our machines equip with automatic lubrication system.When working,the whole machine is covered against noise,dust and danger.

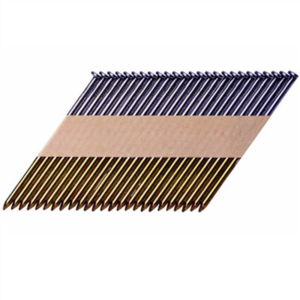

- This type machine is well used for normal nail,D-head nail,coil nail,paper strip nail and blind rivet nail making.

Machine Feature:

- High productive with Max 800pcs/min

- Defective rate:With tiny rate which even can ignor.

- High productive with higher product quality,Continue working with labor saving 30% more.

- Especially best machine for coil nail making ,the high quality nail bring high level quality coil nail and without nail sorting before welding.

- Operating and maintain are much easier than before.As our machine developed every year,Wuxi United Machinery produce the high-performance automatic steel nail making machinery by utilizing innovative sensor technology to enable extensive quality control and fast trouble shooting.

- The active wire pay-offcould used for load coil wire with max 1.5ton which much save machine pause time and make you better operating experience.

- Machine working space less ,Machine working noise lower ,Machine working with longer time nail cutter re-sharping times. All bring you working much confortable than before.

- Nail cutting scrap and nice finished nail collect sperate.the workshorp become much cleaner and product move fast to next section.

- By change the machine tool,machine can used for different type nail making ,like D head,steel nail,concrete nail ,paper strip nail and so on.

Finished Products:

Q:What is the biggest difference for the high speed nail making machine and traditional nail making machine?

A:our revolutionary high-speed nail machines that are a cut above conventional nail machines. Unlike traditional “cut-and-hammer” processes, our machines enable wire feeding, cutting, and head forming to occur seamlessly in one continuous process. This innovative method ensures the fastest and most reliable production of top-quality steel nails.

Our machine boasts an impressive capacity, capable of producing up to 800 nails per minute. It is perfect for workshops prioritizing automatic in-line setups. With proper training, a single operator can effortlessly handle more than 10 machines, resulting in labor cost savings of 50-70%.

By choosing our high-speed nail making machines, you’ll not only save valuable working space but also enjoy a quieter manufacturing process, which is more operator-friendly.

Rest assured that all machine parts are manufactured in-house, guaranteeing exceptional quality. We take pride in offering the best prices for spare parts and ensuring fast delivery times, providing you with unparalleled support.

Discover the future of nail manufacturing with our high-speed nail making machines. Experience efficiency, reliability, and superior quality like never before.

Q:What kind nail can be made by the high speed nail making machine?

A:The machine we offer is a state-of-the-art high-speed, energy-saving equipment specifically designed for producing high-quality pneumatic nails and ordinary loose nails. It is particularly suitable for manufacturing coil nails and normal nails that require small diameters, large nail heads, and consistent nail shanks.

With its advanced features and efficient operation, this machine not only ensures top-notch nail production but also optimizes energy usage, making it an environmentally friendly choice. By investing in this high-speed, energy-saving equipment, you can achieve superior nail quality while minimizing energy consumption.

Q:What is the cost of the high speed nail making machine?

A:The price of a high-speed nail making machine can vary depending on various factors such as the brand, model, features, and range from 18,000usd to 38000usd.

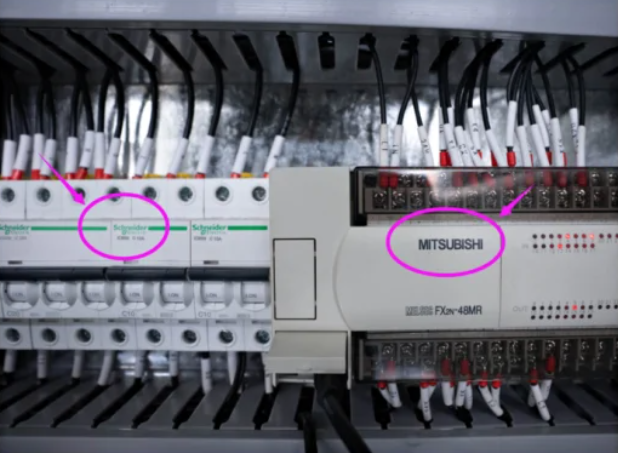

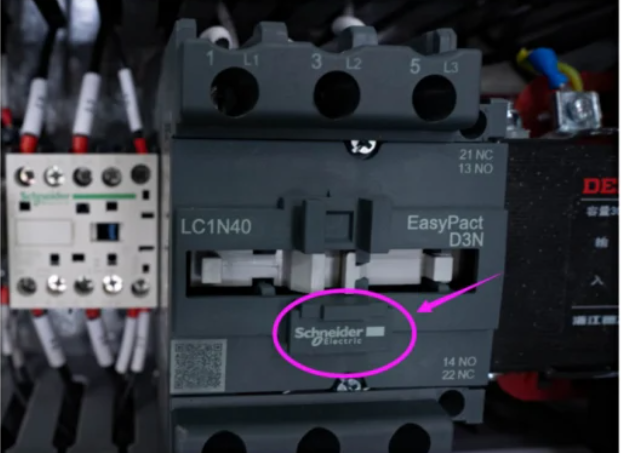

At our company, we prioritize quality and reliability in the manufacturing of our high-speed nail making machines. We understand the importance of using high-grade materials and trusted electrical parts to ensure the longevity and performance of our machines.

When it comes to material selection, we carefully source and utilize only the finest quality components. From the frame to the cutting mechanisms, we choose durable materials that can withstand the rigorous demands of high-speed nail production. This helps to ensure that our machines maintain a consistent level of performance over time, reducing maintenance costs and maximizing productivity.

In addition to superior materials, we also partner with reputable electrical component suppliers. We understand that the electrical system plays a crucial role in the functionality and safety of our machines. By using big brand electrical parts, we can guarantee the reliability, efficiency, and safety of our high-speed nail making machines. These components are known for their durability, precision, and adherence to industry standards.

By combining high-grade materials and big brand electrical parts in our machines, we provide our customers with a product that is built to last, perform consistently, and meet the highest quality standards.

Q:What after-sales service does United Machinery provide?

A:United Machinery is committed to providing customers with comprehensive technical support services, even after the warranty period ends. Our technical staff will respond promptly to any customer feedback by email or phone to resolve issues and provide timely solutions.

We also ensure that spare parts are replaced in a timely manner if they are found to be damaged during operation. Each machine comes with a recommended list of spare parts, which we advise customers to keep readily available to avoid any production interruptions. These may include nail molds, nail knives, punch pins, wire drawing dies, barbed wire cutters, fence machine molds, grinding wheels, and more.

Q:What are the advantages of united Machinery?

A:United Machinery takes pride in leading a team with a strong service intent, open communication channels, and a customer-oriented approach to deliver customized solutions promptly. We support our clients every step of the way, from machine consultation, factory drawing, machine capacity analysis, machine on-line demonstration, to machine installation and commissioning. Our materials are sufficient, and we use internationally and China renowned brands for motors, electrical components, and reducers. United Machinery products are finely polished and painted, and customers can customize colors, logos, nameplates, etc. according to their requirements. Our machinery has passed ISO9001:2015 certification, and we take pride in being a noteworthy manufacturer, exporter, and supplier of wire and nail machinery for over 30 years.