Dry wire drawing machine

Our Dry wire drawing machine is well known as OTO Type Wire drawing machine,Vertical Type Wire drawing machine and Pulley Type wire drawing machine and so on.

Video:

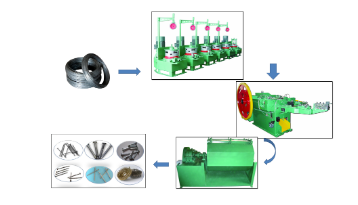

Steel wire drawing for Nail manfacturing layout

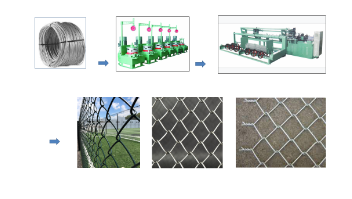

Steel wire drawing for fence manufacturing layout

Application:

It is an ideal equipment for drawing wire stock of high,medium and carbon steel ,as well as copper,aluminum,and alloy.The machines are widely used for drawing wire in the factories such as wire steel factory,mental mesh factory,nail making factory and etc.- The equipment consist of main reduction gear box,die box,drawing capstan and electric control system,the drawing blocks are fixed on the casted iron box and gear luburicated by oil.

- In order to lower residual heat on the surface of capstan,the capstans are water cooled and air cooled.

Technical specifiction

| Model | Unit | LW-1-6/560 | LW-1-7/450 | LW-1-6/350 |

| Material intensity | kg/mm2 | δb≥110 | 128 | δb≥140 |

| Max diam of material | mm | 6.5 | 3.4 | 2.5 |

| Min diam of material | mm | 2 | 1 | 0.75 |

| Diam of block | 1-6/560 | 1-7/450 | 1-6/350 | |

| Max average condensation | % | 30% | 20% | 21% |

| Total condensation | % | 78-88.5% | 77.90% | 78% |

| Max.speed of block | m/min | 245 | 346.9 | 200 |

| Total power | kw | 18.5-30 | 7.5-11 | 7.5-11 |

| Weight | kg | 2000kg | 1500 | 1000 |

| Overal size | mm | 1700x1150x1750 | 1520x810x1700 | 1400x800x1500 |

Machine Feature:

- Multi Speed, Block Type, Continuous Dry Wire Drawing Machines

- Capstan : 560 / 450 /350mm

- inlet:6.5to 1.6mm

- finish:2.8-1.0mm

- Speed:200 to 346.9meter per mins

- Drive:Frequency Converter Variable Speed Control

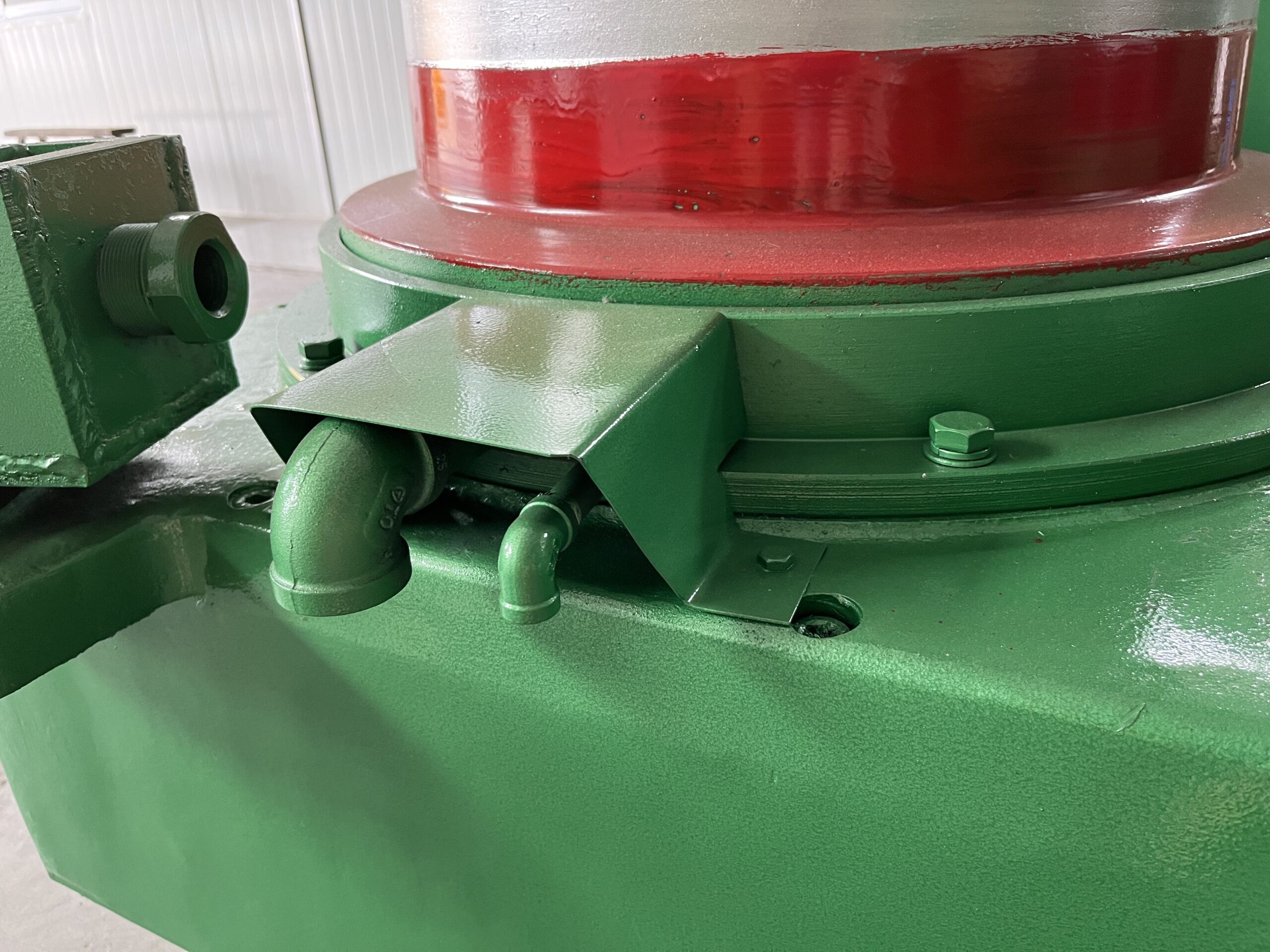

- Water cooling inner drawing capstan

- Independent Control Desksupport for operator

- Continue wire drawing , independent die box on each block,wire can draw by passing the die and accumulated on the drum ,then turn to next die to drawing so that the wire thickness could change step by step.

- High grade Cast Iron Drum body with suface Chrome Carbide hard treating

Accessories

- Wire rod payoff machine

- Shuncking machine

- FZ sharpening machine

- UN butt welding machine

- Trunk wire winding machine

Pully type wire drawing machine FAQ

In case you’re eager to know what a wire drawing is and you can’t get a straight answer, we’re here to help you gain a bit more understanding of that. Tired of spending hours browsing through pages and websites trying to find the right answers you’re looking for? Look no further, because this ultimate FAQ guide covers all your questions in one convenient location. Here you will find comprehensive information on all aspects of a pulley type wire drawing machine & detailed descriptions outlining its various components. We’ll even provide useful advice from industry experts guaranteeing that whatever challenges come up – we have solutions! So embark on a journey with us, uncovering the mysteries surrounding the pully type wire drawing machine now!

1.What is the pully type wire drawing machine?

The pulley type wire drawing machine is a versatile machinery, essential to those industries that require reducing the diameter of steel wire. It has applications in a wide range of industries including decoration, construction and steel wire manufacturing,steel nail making machine.

The most popular usage with our pully type wire drawing machine like bellow:

- Low carbon steel nail manufacturing

- High carbon steel nail manufacturing

- Wire mesh manufacturing

- Annealing wire manufacturing

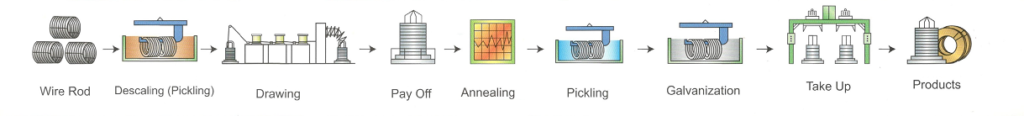

How does the pully type wire drawing machine working?

For low/high carbon steel nail manufacturing,wire mesh manufacturing and annealing wire manufacturing, you need a reliable machine that can produce high quality materials in a fast, efficient manner. Here we will recomend you our pully wire drawing machine(dry wire drawing machine). This multi-speed, block type, continuous dry wire drawing machine offers a capstan of 560/450/350mm for initial inlet of 6.5 to 1.6mm and an impressive finish of 2.8-1.0mm. The speed is 200 to 346.9 meters per minute, and the frequency converter variable speed control offers added flexibility. Additionally, an independent control desk is available for operators to make sure the machine is running optimally.

The machine is designed for efficient, continuous wire drawing. Each block has an independent die box, allowing you to draw and accumulate wire on the drum before you pass it on to the next die for even lower thickness. The high grade cast iron drum body is chrome carbide hard treated, making sure that it stands the test of time.

As you can see, first pls tell the steel number ,wire diameter input and output,we could calculate the drawing machine block quantity according to those detail.As soon as we confirm the drawing input and output diameter,we could fix custom wire drawing die on each drawing block.When wire pass each block,the wire diameter will step by step to arrive the final size you need.

Parts of Pully wire drawing machine

Today, there have been many different versions of wire drawing machine that you could choose from in the market. However, traditional and classic drawing machine are typically comprised of the following:

Drawing capstan

The drawing capstan is the primary mechanism of a drawing machine.Crafted with precision and engineered for excellence, this high-grade Cast Iron capstan is durability and reliability. Specially designed to elevate your drawing experience, it boasts a Chrome Carbide hard treating surface that guarantees exceptional performance every time you harness its power.

Reduction Gear box

Each drawing block gear box is crafted with high precision and attention to detail, ensuring wire drawing seamless transition from big diameter wires to smaller ones, step by step.

Die box

Each drawing block in drawing group is with a drawing die box. The drawing die box is capable of accommodating different sizes of drawing dies. In addition, there is a nearby tank specifically designed for feeding drawing powder. This powder serves as an effective lubricant during the wire drawing process.

Motor:

Each drawing block in the drawing group is equipped with a vertical motor that is connected to a reduction gear box. When the motor is powered on, the motor drives the gearbox to start working. This causes the capstan to turn in the same direction, starting from No. 1 and continuing to the last capstan. Simultaneously, the capstan pulls the wire through the die and accumulates it onto the next capstan. This process helps to reduce the thickness of the material step by step.

Electric control cabinet

The electrical cabinet allows for full control of all drawing blocks, ensuring safety and convenience for operators. In the event of wire breakage or entanglement, the control desk allows for immediate stopping of the operation.

Convetor

Our convetors have been designed with your convenience in mind, allowing you to easily adjust the drawing speed of each block, all while maximizing efficiency and minimizing energy consumption. Say goodbye to clunky, unpredictable drawing processes and hello to seamless, stable drawing .

How much do the wire drawing machine cost?

The prices of wire drawing machine line vary on many factors like the steel number, the wire diameter input and output, capstan size,motor specification and the drawing capacty and so on. If you were to ask the average price of weld rotators, though, it ranges between $5,000 and $50,000.

By offering these options, we ensure that you have the flexibility to choose the best solution for your needs.

Why Wuxi United machinery is Your Best Bet For wire drawing solution?

Wuxi United Machinery is widely regarded as a leading provider of wire drawing solutions, thanks to their cutting-edge technology and extensive expertise in wire drawing machine, nail making machine, barbed wire making machine, and chain link fence making machine. They are known for their automated processes that ensure efficient and high-quality machine production. Wuxi United Machinery offers a range of wire drawing machines, including the pully type model, which boasts features such as high quality, various choise, minimal impact, and exceptional accuracy.

One notable aspect of Wuxi United Machinery is their wealth of experience in handling wire drawing projects of various scales in different countries. They have the knowledge and capabilities to assist you throughout the entire process, from designing a complete production line to providing support until the machines are successfully commissioned in your workshop. Their expertise and customer-centric approach make them a reliable choice for your nail making needs.

What Else Do We Offer?

At wuxi United machinery, we offer more than just wire drawing machines. Our extensive range of products includes Nail making machines, High speed thread rolling machines, High speed coil nail welding machines, Barbed wire making machines, Chain link fence machines, wire straighten and cutting machines, and all machine spare parts.

To receive a free quotation, simply contact us through any of our available channels. Rest assured, our dedicated representative will respond within 24 hours to gather more specific details about your order.

Don’t hesitate, reach out to us today and receive a quotation tomorrow! Our team is here to assist you with your needs.

Pingback: sans ordonnance pas cher kamagra

Pingback: how to order enclomiphene canadian pharmacy no prescription

Pingback: cheap androxal no prescription mastercard

Pingback: buying dutasteride overnight no rx

Pingback: buy flexeril cyclobenzaprine buy adelaide

Pingback: how to order gabapentin generic in united states

Pingback: buying fildena purchase toronto

Pingback: ordering itraconazole uk london

Pingback: how to order staxyn australia online no prescription

Pingback: purchase avodart generic tablets

Pingback: does xifaxan need a prescription

Pingback: were can i get generic rifaximin online cheap

Pingback: přes přepážku kamagra alternativa