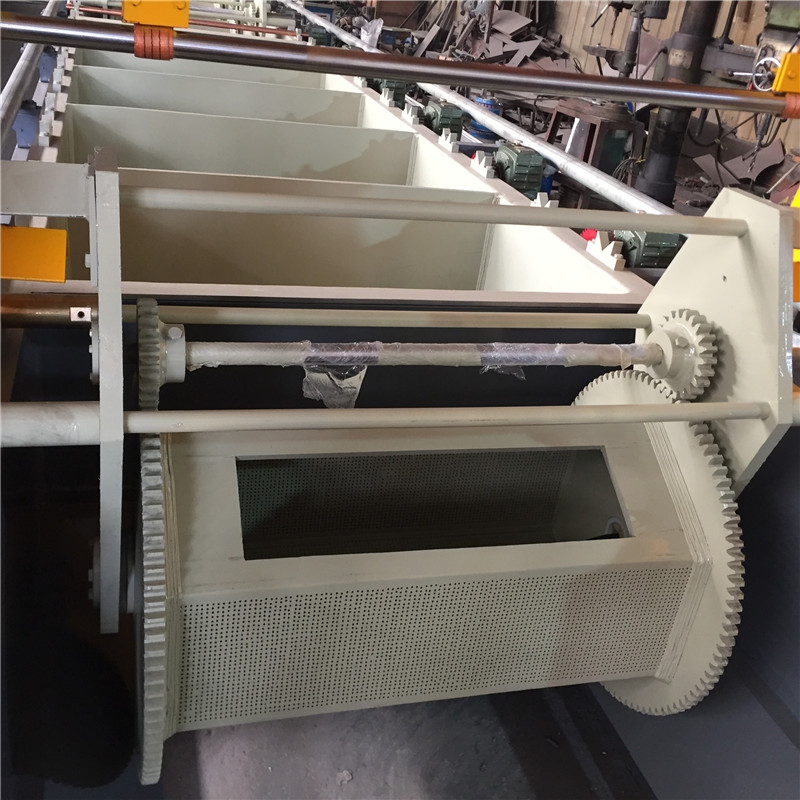

Electroplating machine

- Electroplating machine -Gantry type barrel electroplating machinery

- It is a process of forming uniform, dense, combined with good metal or alloy deposited layer on workpieces surface after the effect of electrolysis.

- Compared with other metals, zinc is relatively cheap and easy plated metal, and also is a low corrosion plating layer, which is widely used to protect steel parts, in particular to prevent atmospheric corrosion, as well as used for decoration filed.

Video:

Application:

- Electroplating machine -Gantry type barrel electroplating machinery

- It is a process of forming uniform, dense, combined with good metal or alloy deposited layer on workpieces surface after the effect of electrolysis.

- Compared with other metals, zinc is relatively cheap and easy plated metal, and also is a low corrosion plating layer, which is widely used to protect steel parts, in particular to prevent atmospheric corrosion, as well as used for decoration filed.

- Electric galvanized plating machine technical processes:

- Chemical degreasing → Water rinse → Electric galvanized zinic → Rinse → Passivation →Rinse →Hot Water rinse → Rinse → drying

Machine Feature:

- Semi-automatic production line .

- Applied to hardware metal parts barrel plating producing.

- Readily for transforming process and plating time.

- The main machine, uses Brand motors with brake. Therefore, with advantages of smooth running, reliable brakes, less shaking

- It can transform any process and procedures easily. Then can fit different parts electroplating and time requirements.

- Maximum lifting weight: could be designed according to final product.

- Working conditions: continuous production for 24 hours.

- Suitable for galvanized, nickel, tin, and other electroplating.

Finished Products: