Specifications:

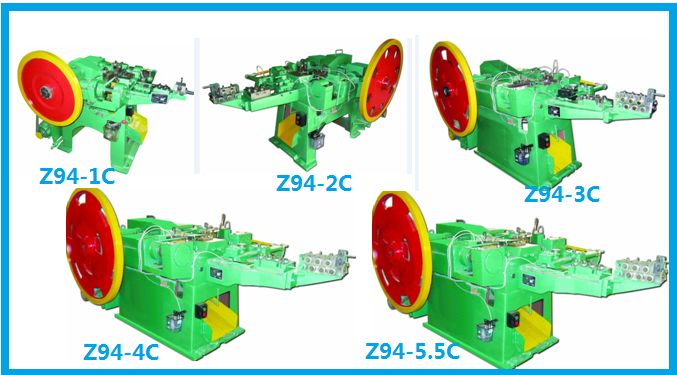

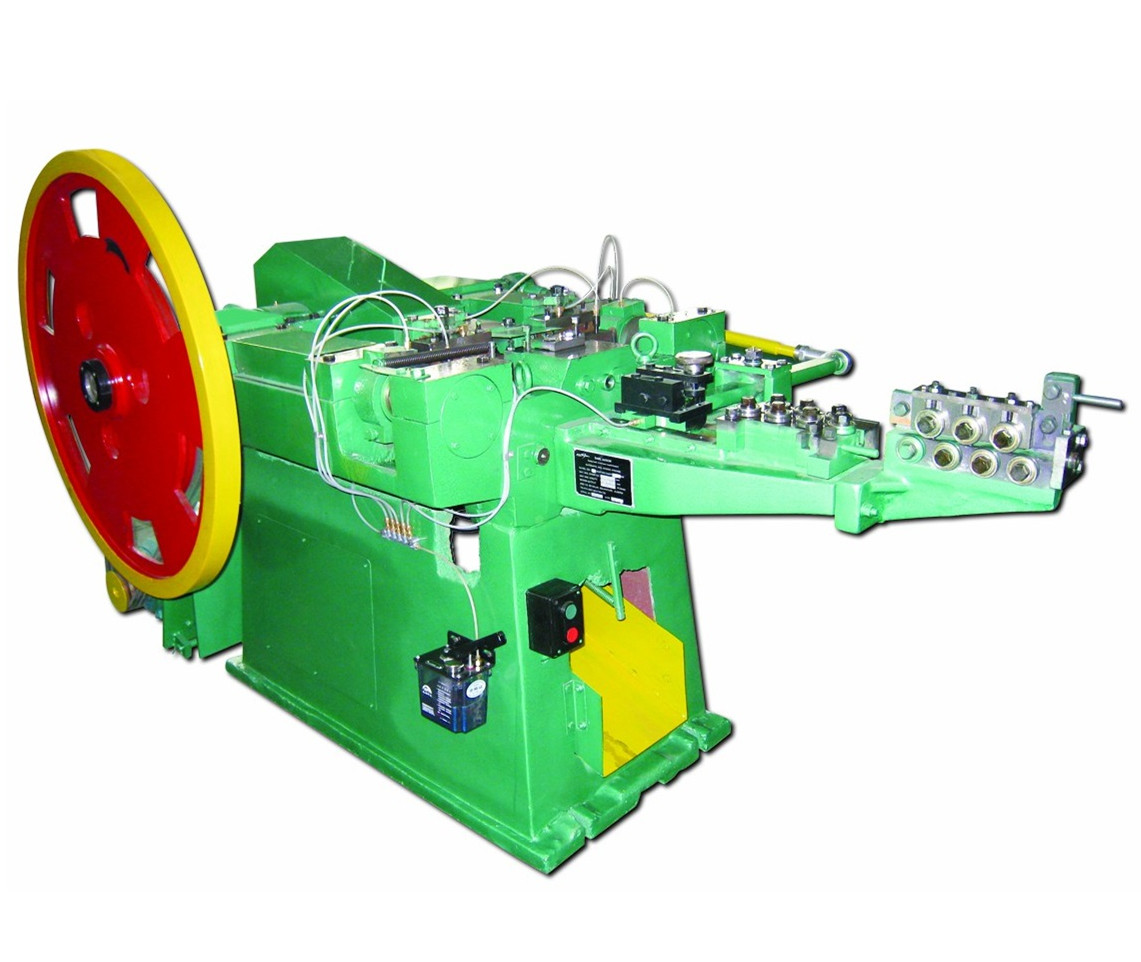

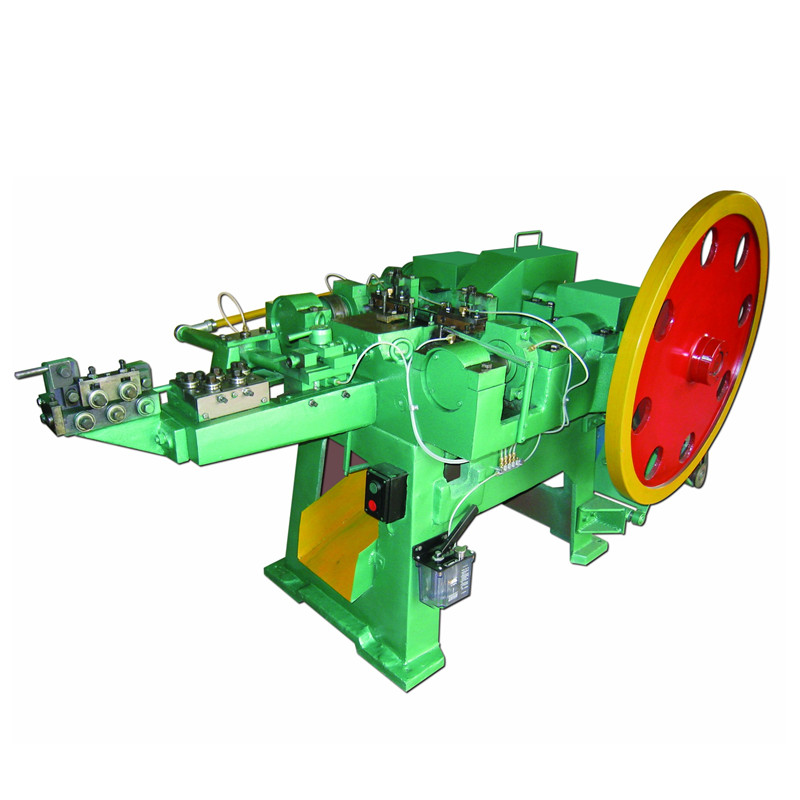

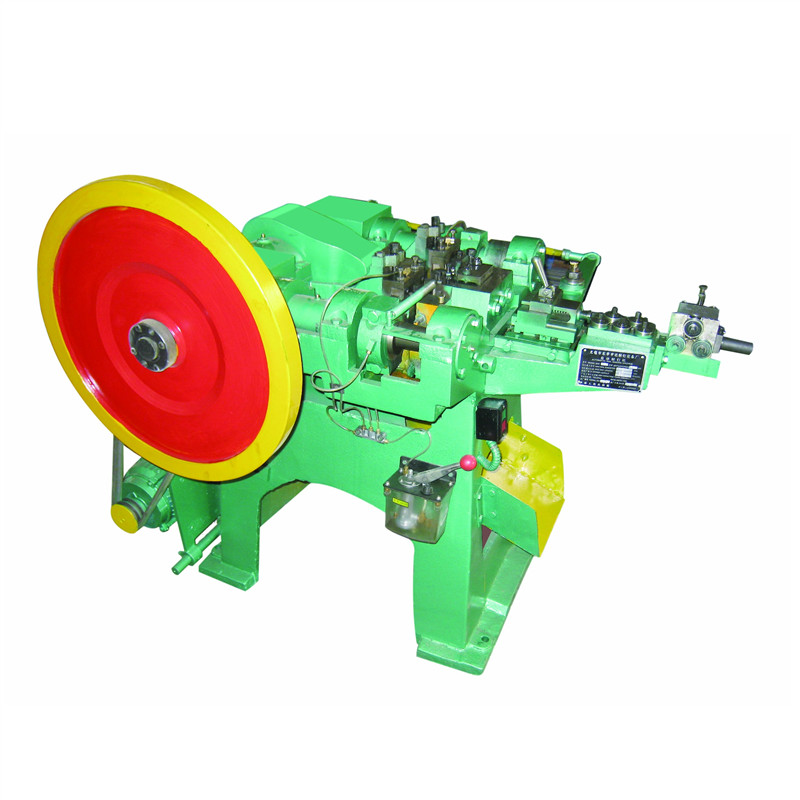

Z94 Type Automatic Nail Making Machine

Z94 series High speed ,low noise nail making machine usually used to make normal nail,concrete nail,steeless nail,D shape , T shape nail and other shaped nail usded for high speed welding nailer and nail gun.

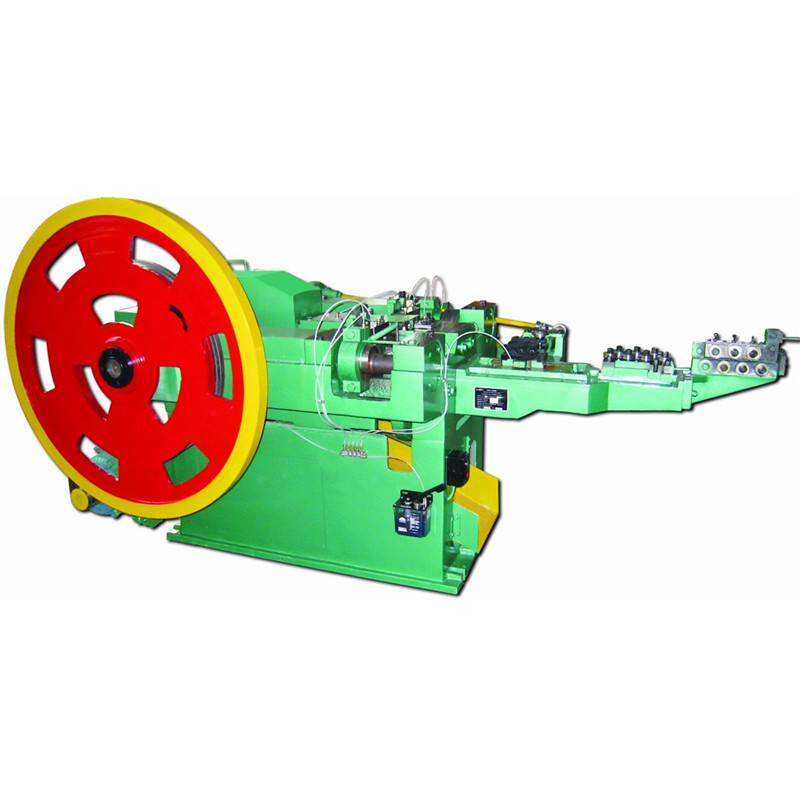

Z94-6.5C

| Parameter | Unit | Z94-6.5C |

| Dia of nail max | mm | 6.5 |

| Dia of nail min | mm | 4.5 |

| Length of nail max | mm | 200 |

| Length of nail min | mm | 100 |

| Dsigned out put | pcs/min | 160 |

| Moter power | kw | 11 |

| Weight(approx) | kg | 5000 |

| Overall dimensions | mm | 3200x2200x2200 |

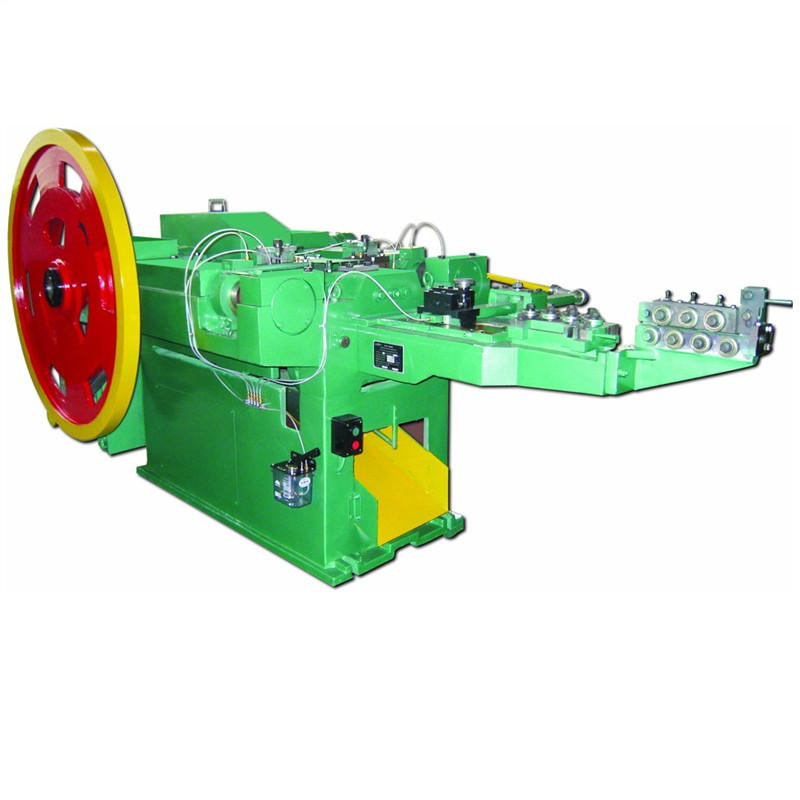

Z94-5.5C

| Parameter | Unit | Z94-5.5C |

| Dia of nail max | mm | 5.5 |

| Dia of nail min | mm | 3.7 |

| Length of nail max | mm | 150 |

| Length of nail min | mm | 80 |

| Dsigned out put | pcs/min | 200 |

| Moter power | kw | 5.5 |

| Weight(approx) | kg | 2500 |

| Overall dimensions | mm | 2800x1800x1800 |

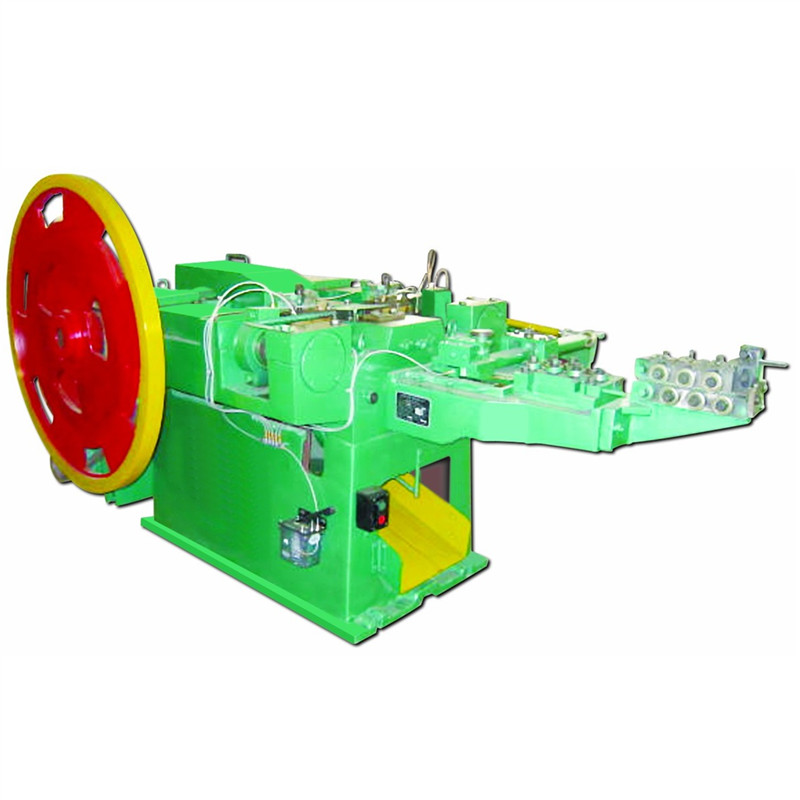

Z94-4C

| Parameter | Unit | Z94-4C |

| Dia of nail max | mm | 4.5 |

| Dia of nail min | mm | 2.8 |

| Length of nail max | mm | 100 |

| Length of nail min | mm | 50 |

| Dsigned out put | pcs/min | 260 |

| Moter power | kw | 4 |

| Weight(approx) | kg | 2000 |

| Overall dimensions | mm | 2200x1600x1650 |

Z94-3C

| Parameter | Unit | Z94-3C |

| Dia of nail max | mm | 3.4 |

| Dia of nail min | mm | 1.8 |

| Length of nail max | mm | 80 |

| Length of nail min | mm | 30 |

| Dsigned out put | pcs/min | 320 |

| Moter power | kw | 3 |

| Weight(approx) | kg | 1400 |

| Overall dimensions | mm | 2000x1400x1400 |

Z94-2C

| Parameter | Unit | Z94-2C |

| Dia of nail max | mm | 2.8 |

| Dia of nail min | mm | 1.2 |

| Length of nail max | mm | 50 |

| Length of nail min | mm | 16 |

| Dsigned out put | pcs/min | 350 |

| Moter power | kw | 2.2 |

| Weight(approx) | kg | 1200 |

| Overall dimensions | mm | 1700x1300x1400 |

Z94-1C

| Parameter | Unit | Z94-1C |

| Dia of nail max | mm | 1.6 |

| Dia of nail min | mm | 0.9 |

| Length of nail max | mm | 25 |

| Length of nail min | mm | 9 |

| Dsigned out put | pcs/min | 450 |

| Moter power | kw | 1.5 |

| Weight(approx) | kg | 560 |

| Overall dimensions | mm | 1500x1300x1200 |

Application:

- Z94 series High speed ,low noise nail making machine usually used to make normal nail,concrete nail,steeless nail,D shape , T shape nail and other shaped nail usded for high speed welding nailer and nail gun.

- This type equipment adopts plunger type structure so as to ensure the features such as high speed ,low noise and less compact.

- It consist of lubricating systerm and driving systerm,The driving systerm include wire feeding,wire clamping ,wire cutting and stamping.Feature with simple struction ,low power comsuption and easy to maintain.

Machine Feature:

- key components (crankshaft,cramConnecting rod,gear,side shaft) are made of high-grade steellike 40cr,45#steel casting ,45#steel forging ect.

- Machinewith plunger structure make the nail making with few impact ,nice forming and with small power consumption.

- Length can adjust on each model machine,Diameter different by change the nail mould.

- Machine developed with less spare part which make the operating easier and maintain friendly .

- Each machine strictly inspect and well packed before shipping.As soon as machine arrived,you can fix on the concrete ground and start working at once.

- Machine install and commision service available .

- Wholeyear on line support,any technical problem or machine parts requirment ,we could support with 6 hours.

Video:

Finished Products:

Frequently Asked Questions about Nail Making Machine

Q:How to make nail?

A:A nail made by nail making machine is typically a steel rod with a pointed end and a formed head, used to join pieces of wood or other materials. It can also be made from other metals including aluminum and brass.

The Process of Manufacturing Nails

Nails are typically created from metal wire coils. This wire is introduced into a nail making machine capable of producing up to 450 nails per minute. The nails can then undergo further modifications, be cleaned, finished, and finally, packaged.

Formation Stage

- A coil of wirestand on the wire payoff is pulled and directed into the nail making machine, where it’s held by a pair of gripping dies. The dies have been previously shaped to form the head of the nail.

- While the dies keep the wire in place, a mechanical hammer strikes the free end of the wire, deforming it into the die cavity to create the nail head.

- The wire remains clamped in the dies, a set of shaped cutters hit the other end of the nail, forming the point and separating the nail from the rest of the wire coil.

- The dies open, and an ejector mechanism knocks the nail into a collection pan beneath the machine. The free end of the wire is drawn from the coil and fed back into the machine. The cycle then restarts.

Additional Formation

- Nails requiring helical twists, serrations, or other surface configurations are fed into High speed thread rollingmachines or other machines that roll, twist, stamp, or cut them into required forms.

Finishing Stage

- The nails are cleaned in Nail polish machine filled with wooden powder. This process removes any oil from the nail manufacturing machine and eliminates any minute metal scraps, or nippings, attached to the nails.

Packaging Stage

- Packed by labor:the finished nails sent to weighing machines;Or we can buy extra nail packing machine :Magnetic elevators transport nail to weighting machine, As the nails fall in, a magnetic field aligns them into neat rows. Once packaged, the nails are demagnetized. Nails are generally sold in boxes of 1, 5, 10, 25, and 50 KG.

Q:What is the main spare parts of the nail making machine?

A:1.Nail mould/Grip die

The nail mould is consist by 2 pcs .One short and one long.It is installed at the supporting surface of the mold table, at the middel of the front-part of nail making machine.As soon as the wire feed into the nail making machine working center.The nail mould used to clamp or release the wires.

2.Nail knife/Nail cutter

There are two groups of cutting mechinism which stand face-to-face on the two

different side shafts.and our nail knife fix each side.The turing of the cams on the two side shafts will drive the left and right nail knife slider move left and right, as to cut the nail point when the nail knife on them fit together.

3.Punch pin

Our Punch pin fix at the end of the nail making central slider.Roating of the crankshaft will drive the slider to punch the nail head successfully.

Q: What types of nails can be produced with a Nail Making Machine?

The Series Z94 high efficient,low noise with super performance automatic nail making machinery are mainly used for manufacturing steel nails between the length of 9mm to 200mm(0.5’’-8’’) and diamter of Ф0.9-Ф6.5mm;and after little reformation,the machine is also able to manufacture other steel nails with special specifications,such as double-cap nail,felt nail,V-nail,corrugated plate nail,U-nail,gun nail and the like.The manufactured nails can be extensively used in industry,building,Packing and ect.

Q: What is the production capacity of a Z94 Nail Making Machine?

A: The production capacity of Z94 Nail Making Machine can vary depending on different model which from 150-450 pcs/min.There are 6 different model for the normal steel nail making ,and different model have a range size for nail making.The guideline we recommend is to utilize smaller models for small nail production and larger ones for big nail creation. The reason for this is that smaller nails, despite their diminished power, can be produced rapidly and in large quantities by our smaller models. In contrast, the production of larger nails requires more power, achievable exclusively through the use of our larger machines.

Q: What is a common issue encountered during nail production?

A:When it comes to steel nail production, there are several common problems that can arise. However, with the right approach and trouble shooting techniques, these issues can be effectively resolved. Here are some steps to solve common problems when making steel nails:

- One common issue that occurs is the absence of a nail cap, which can be attributed to the clamp’s inability to securely hold the nail wire. To rectify this, simply replace the clamp. Another potential cause is the length of the reserved nail wire used for punching the nail cap. If it is too short, adjusting the length can solve the problem.

- The nail cap typically exhibits a non-round shape, which is often attributable to a corresponding flaw in the fixture. Firstly, carefully inspect the fixture’s countersunk hole to determine if it is round. If it is not, it necessitates re-drilling. Additionally, it is crucial to observe and adjust any irregularities in the fixture’s die hole to ensure smooth operation. Another potential issue could be related to the nail wire. If the reserved nail wire for punching the nail cap is too short, adjust its length accordingly. Alternatively, if the nail wire is excessively rigid and unable to penetrate the nail cap, or if the nail cap itself is deemed substandard, annealing of the nail wire becomes necessary.

- Nail Cap Thickness: Ensure that the fixture has consistent height for both pairs, along with the ability to securely clamp the nail wire. Additionally,adjust the punch screw which on the plunger can adjust the nail cap thickness. Lastly, assess the nail wire’s hardness and the quality of the punched-out nail cap to determine if they meet the desired standards.

Q: What is the price range for a Nail Making Machine ?

A:The price of a nail making machine can vary based on several factors, such as the manufacturer, the materials used in its construction, and the size and type of nails it can produce. On average, the cost of a nail making machine falls within the range of $2,800 to $16,800.

To accurately determine the quantity of machines needed for a complete nail making line budget, it is helpful to have a detailed list of each machine’s nail size making capacity, as well as the working hours per day and per month. This information allows for better calculation of the required auxiliary equipment and spare parts.

Q: How to choose a Nail Making Machine ?

A:Before finalizing your decision on which nail making machine to purchase, it’s essential to make sure you’re not only getting the best quality but also the specific machine that will suit your project requirements.

Here are some key factors you should consider before acquiring a nail making machine:

Nail kind and size

Firstly, it’s imperative to determine the exact type and size of the nail you want to manufacture. You can gauge this by identifying the most prevalent type of nail in your local market. As we known, no single machine can cover all types, shapes, and sizes of nails. Our nail making machines are designed in varied models and structures to cater to your unique nail making requirements.

Power requirment

Understanding the voltage requirements and power output of your nail making machines is crucial for allocating the right amount of energy or electricity. Additionally, it is important to consider the wattage capacity of your plant and avoid plugging the machines into incorrect outlets, as this can lead to short circuits and potential damage. Take the time to investigate and comprehend the power requirements of your planned quantity of nail-making machines to prevent any mishaps or issues down the road.

Raw material

The typical material used for making nails is low carbon steel, specifically Steel numbers Q195/Q235 or SAE1006, SAE1008, SAE1010, SAE1012, SAE1016. If the local market offers a variety of raw materials with different diameters, it would be of great assistance. However, if the local market doesn’t provide such options, we would need to procure the raw material from other markets. Alternatively, we can consider purchasing a Wire Drawing Machine Line to draw the wire accordingly.

Q: Where can you get the high-quanlity nail making machine ?

There are numerous places where you can find top-notch nail making machines. Particularly in Europe, countries like Denmark and Germany are known for offering high-quality options. However, it’s worth noting that these machines often come with a higher price tag, potentially exceeding your allocated budget.

For those seeking high-quality and affordably-priced nail making machines that perform optimally, Asia, specifically China, serves as the ideal destination.

In our country, there exists a multitude of nail making machine and equipment manufacturers who strive to deliver the exceptional quality you desire.

Amidst this wide array of options, Wuxi United Machinery stands apart as the preferred choice for nail making solutions. Our extensive expertise encompasses technical and specialized component-related solutions, as well as industry-wide improvements.

With a team of skilled engineers and experts, we are dedicated to meeting all your needs and offering

Q:Why Wuxi United machinery is Your Best Bet For nail making solution?

Wuxi United Machinery is widely regarded as a leading provider of nail making solutions, thanks to their cutting-edge technology and extensive expertise in wire drawing machine, nail making machine, barbed wire making machine, and chain link fence making machine. They are known for their automated processes that ensure efficient and high-quality machine production. Wuxi United Machinery offers a range of nail making machines, including the dependable Z94 model, which boasts features such as high speed, low noise, minimal impact, and exceptional accuracy.

One notable aspect of Wuxi United Machinery is their wealth of experience in handling nail making projects of various scales in different countries. They have the knowledge and capabilities to assist you throughout the entire process, from designing a complete production line to providing support until the machines are successfully commissioned in your workshop. Their expertise and customer-centric approach make them a reliable choice for your nail making needs.